Description

2-inch cryo-trap designed for use with the SIS AutoDesorb System

New Programmable Micro Cyro-Cooling and Heating Trap for the Cryo-focusing of Volatiles and Semi-volatiles at the Head of GC Capillary Columns designed for use with the AutoDesorb System.

AutoDesorb Cryo-Trap

The 2" long Cryo-Trap was specifically designed for use with the new SIS AutoDesorb system. It has been designed to mount inside the GC oven just under the GC injection port. It mounts to the top inside oven wall around the GC injection port. It does not mount directly to the injection port like our previous Micro-Cryo Trap. Since it does not physically mount onto the injection port, there is no heat drain from the injection port. This was designed this way to eliminate any possible heat drain from the GC injection port heater circuit.

Features

- Designed for use with the Agilent 6890/7890 GC

- Software programmed and controlled by SIS AutoDesorb System

- Mounts to the GC Injection Port inside the GC Oven

- Only 2.0" Long - Uses minimum amount of cooling gas

- Reduction of CO2 or LN2 use by 97% as compared to cooling the entire oven.

- Improve Chromatographic resolution of early eluting peaks

- Dual programmable cryo-cooling and heating cycles

- Heating and Cooling set and controlled by a PC Window Screen

- Trap compounds in the GC oven at the head of the GC column.

- Rapid heating up to 400 deg C at > 1000 deg C per minute.

- Cool to -70 deg C using Liquid CO2

- Cool to -180 deg C using liquid LN2

Theory of Operation

Cryo-trap in GC oven.

Cryo-trap in GC oven.

Diagram of cryo-trap.

Diagram of cryo-trap.

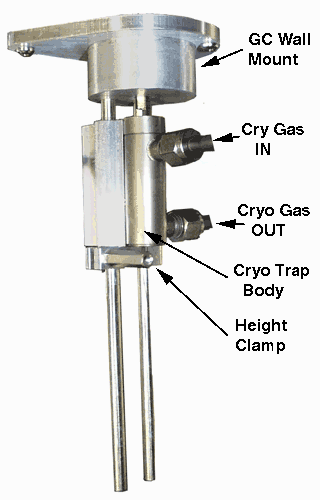

Details of the 2" Cryo-Trap

The Cryo-Trap consists of a small heating/cooling chamber which is 3/4" in diameter and 2.0" long which mounts to the bottom of the GC injection port just inside the GC oven. In the center of the chamber is a small stainless steel capillary through which the fused silica capillary column freely passes. Capillary columns up to megabore (0.53mm I.D.) diameters can be used. Around the stainless steel capillary tube a heating coil is wound to provide for the rapid heating of the capillary tube. A thermocouple provides accurate measurement of both the cooling and heating temperatures. Either Liquid CO2 or Liquid Nitrogen for cooling is introduced into the Cryo-Trap (Cooling Gas In), and is exhausted through the outlet. The exhaust can either be vented into the GC Oven or a tube can be attached to vent the cooling gas external to the GC.

Picture of cryo-trap in GC oven.

Picture of cryo-trap in GC oven.

2" Cryo-Trap for the AutoDesorb System mounted inside the Agilent 6890 GC

The adjustable mount permits the repositioning of the Cryo-Trap vertically after it is installed to enable the easy installation of GC columns to the injection port. A hex handled clamp permits tightening the trap in place on the two guide rods.

Purge & Trap of Black Tea, before and after cryo-trapping.

Purge & Trap of Black Tea, before and after cryo-trapping.

Trapping Efficiency of Hydrocarbons on 0.53 mm DB5 (1.5u film thickens) at various

cryo-trapping temperatures 0 to -180 °C.

Trapping Efficiency of Hydrocarbons on 0.53 mm DB5 (1.5u film thickens) at various

cryo-trapping temperatures 0 to -180 °C.

AutoDesorb System and Components

In addition this new Cryo-Trap can be used for either LN2 or CO2 cooling gas use. The AutoDesorb system will automatically detect the type of cryo trap and load the correct software to correctly control both its heating and cooling. For the cooling operation the cooling gas is pulsed into the chamber. Liquid CO2 will cool down to -70 degrees C. Liquid Nitrogen will cool down to -180 deg. C. The CryoTrap can be used with either LN2 of CO2, but different gas valves must be used for the different gases since they operate at different pressures. The cooling temperature can be set to any temperature between room temperature and the lower limits of the cooling gas.

AutoDesorb Temperature Settings Window Screen

The AutoDesorb Software permits the initial set up of the Cryo-Trap parameters and also permits the temperature and operation of the Cryo-Trap to be monitored during its operation. The PC screen is used to set the CryoTrap heating and cooling temperatures. The PC instructs the microprocessor in the Interface electronics to pulse the cooling gas into the Cryo-Trap chamber to accurately control the cooling temperature to the value you set. The thermocouple provides the feedback to both regulate the temperature as well as display the GC Cryo-Trap temperature on the PC display.

The AutoDesorb system software windows graphically displays the operation of the Cryo-Trap as shown above.

References and Literature

For a complete list of Applications on the use of the Cryo-Trap and other thermal desorption applications see the Applications section of our web site.

- Micro Cryo-Trap Theory of Operation - Description

- Application Note # 38 - A New Micro Cryo-Trap for Trapping of Volatiles at the front of a GC Capillary Column

- Application Note # 19 - Design and Application of the SIS GC Cryo-Trap

- Application Note # 24 - Selection of GC Guard Columns for Use with the GC Cryo-Trap

- Application Note # 28 - Analysis of Volatile Organics in Latex Paints by Automated Headspace Sampling and GC Cryo-Focusing

- Application Note # 29 - Analysis of Volatile Organics in Oil Base Paints by Automated Headspace Sampling and GC Cryo-Focusing

- Application Note # 30 - Comparison of Cooking Oils by Direct Thermal Extraction and Purge and Trap GC/MS

- Application Note # 31 - Volatile Organic Composition in Several Cultivars of Peach by Thermal Desorption with Cryo-Trapping

- Application Note # 34 - Selection of Thermal Desorption and Cryo-Trap Parameters in the Analysis of Teas

- Application Note # 35 - Volatile Organic Composition of Cranberries by Thermal Desorption with Cryo-Trapping

- Application Note # 36 - Identification of Volatile Organic Compounds in a New Automobile by Thermal Desorption with Cryo-Trapping

| Part No. | Description | Quantity In Stock |

Price EA |

Order |

|---|---|---|---|---|

| 976000 | Cryo-Trap for the AutoDesorb | DISCONTINUED | --- | --- |

| 976020 | LN2 valve kit for the Cryo-Trap, includes LN2 valve and tubing | DISCONTINUED | --- | --- |

| 976010 | CO2 valve kit for the Cryo-Trap, includes CO2 valve and tubing | DISCONTINUED | --- | --- |

| 975000 | CRYOTRAP SYST FOR TD5 | 0†Standard lead-time for non-stock items is approximately two weeks depending on the item. | CALL | |

| 975010 | CRYOTRAP CO2 VALVE KIT | 2 | $614.63 | |

| 975020 | LN2 VALVE | 0†Standard lead-time for non-stock items is approximately two weeks depending on the item. | CALL | |

|

* Call for availability. † Standard lead-time for non-stock items is approximately two weeks depending on the item. | ||||

|

|

||||

SIS AutoDesorb® Thermal Desorption System

SIS AutoDesorb® Thermal Desorption System  Short Path Thermal Desorption Accessories Supply Kit

Short Path Thermal Desorption Accessories Supply Kit  SIS TD-5 Short Path Thermal Desorption System

SIS TD-5 Short Path Thermal Desorption System  24 Tube Conditioning Oven for Thermal Desorption Tubes

24 Tube Conditioning Oven for Thermal Desorption Tubes  Thermal Desorption Conditioning Oven - 6 Tube

Thermal Desorption Conditioning Oven - 6 Tube