Description

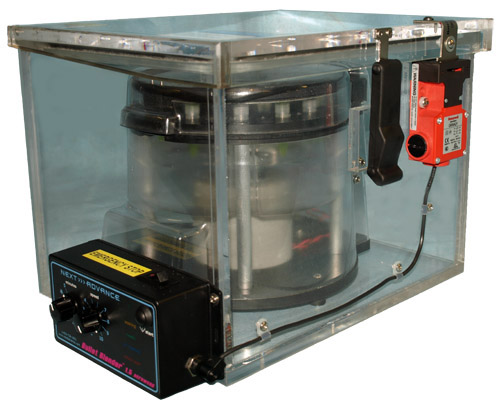

The Bullet Blender® Homogenizer enables you to homogenize, disrupt, or lyse 24 tissue or cell culture samples at a time. Load the samples int polypropylene microcentrifuge tubes, then place them in the Bullet Blender. The "bullets" in the "blender" vigorously strike all the sample tubes simultaneously for a few minutes. The Bullet Blender is available with Air Cooling™ to preserve your sample quality.

- Consistent and High Yield Results: The BULLET BLENDER homogenizer prepares up to 24 samples in just minutes. All of the samples are automatically homogenized in the same manner, with high yields, so there is very little variation from sample to sample. See the Protocols pages for preparation times and speeds.

- No Cross-Contamination or Sample Loss: There are no probes or blades to cause cross contamination or sample loss, which also means there are no parts to clean between runs. The sample tubes are kept closed and self-contained during homogenization.

- Samples Stay COOL: No cool down required. The Bullet Blender homogenizers use very little power due to the unique, patented design. There is very little heating of the samples because the sample tubes vibrate vigorously in air, keeping them cool, rather than being subjected to frictional heating as the tubes rub against the walls of a holder. Also, because the motor does not need to agitate any heavy platforms or plates, it is small and will last for many years.

- So Easy To Use: Simply place your sample, beads and buffer in standard tubes, and load the tubes into the BULLET BLENDER homogenizer. Tune the extent of disruption by adjusting the run time and speed. Afterwards, place the sample tubes in a centrifuge to separate the lysate. No special holders are needed. There are no clamp plates nor locking rings to fiddle with.

Videos

Applications

- Homogenize Tissue - Liver, Spleen, Kidney, Brain, Adipose

- Homogenize Tougher Tissue - Heart, Aorta, Tumor, Tail Snips, Muscle, Lung

- Lyse Cells - E. coli, Mamallian cell culture, Yeast

- Homogenize Plant Material - Leaves, Beans, Nuts, Roots

- Homogenize Small Organisms - Zebrafish, Drosophilia

- Whole Cell Isolation - Bacteria, Lymphocytes, Blood Cells

- Organelle Isolation - Nucleus, Mitochondria

| DNA | RNA | Protein |

|---|---|---|

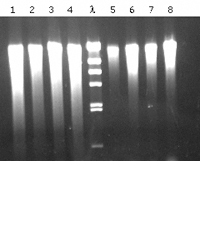

From Plant Samples

Genomic DNA samples in agarose Lanes 1-4 = Tobacco leaf DNA Lanes 5-8 = Rice Leaf DNA samples |

From Tail Snips

Total RNA gel. RNA Integrity (thanks to Madhu Prasad @ |

From E. coli Samples

SDS-PAGE gel stained with wc = whole cell sf = soluble fraction Left two lanes control Right |

Models

| Feature |

|

|

|

|

|---|---|---|---|---|

| High Throughput- Homogenizes up to 24 samples at a time | X | X | X | X |

| Range of speeds allows for gentle vortexing, vigorous homogenization, or anything in between | X | X | X | X |

| Can be used in temperatures ranging from 4 °C to 40 °C* | X | X | X | X |

| With Air Cooling to keep the inside of the instrument near ambient temperature | X | X | X | |

| Can homogenize samples in both screw-cap (#TUBE1R5-S) and snap-cap (#TUBE1EP5-S) tubes | X | X | ||

| Extra-powerful homogenization for tough samples | X | X | ||

| With 4 °C Cooling™ | X | |||

| Made in the USA | X | X | X | X |

Bullet Blender Models: Larger Samples (samples over 300 µl)

| Feature |  |

|

|

|---|---|---|---|

| Homogenization of up to 12 samples from 100 mg – 1 g (100 µl – 1 mL for plant tissue, insects and cell culture) in 5 mL tubes (#TUBE5AX-S2) | X | ||

| Homogenization of up to 8 samples from 100 mg – 3.5 g (100 µl – 3.5 mL for plant tissue, insects and cell culture) in 50 mL tubes (#TUBE50AX-S) | X | X | |

| Range of speeds allows for gentle vortexing, vigorous homogenization, or anything in between | X | X | |

| Can be used in temperatures ranging from 4 °C to 40 °C* | X | X | |

| With Air Cooling to keep the inside of the instrument near ambient temperature | X | X | X |

| With 4 °C Cooling™ | X | ||

| Made in the USA | X | X | X |

Features/Specs

- Size: All BBX and BBY models are 9 in. (23 cm) wide by 11 in. (28 cm) deep by 8.5 in. (21.5 cm) high The BB50-DX model is 15 in. (38 cm) wide by 14 in. (35 cm) deep by 15 in. (38 cm) high The BB24-AU and BB50-AU models are 18 in. (46 cm) wide by 14 in. (35 cm) deep by 15 in (38 cm) high.

- Weight: 8.5 to 33 lbs (4 to 15 kg), depending upon model

- Run Times: UP to 5 minutes (15 minutes for the 50-DX and 50-AU). The Bullet Blender will automatically stop after the selected time is up.

- Power Requirements: BBX24 and BBX24B models: 24 VDC, 0.75 Amp BBY24M and BBX5MB models: 24 VDC,2.5 Amp BB24-AU, BB25-AU and BB50-DX: 100-240 V, 2.5-4.5 A Plug configurations for international wall outlets available

- Operating Temperature: 4 - 40 °C

- Relative Humidity: 5 - 90% non-condensing

- CE certified instruments with upgraded configuration available

- 30 day money back guarantee

- 2 year warranty (extended warranties available)

The Bullet Blender® uses 24 V DC supplied by a small external power supply that plugs into a wall outlet. The appropriate power supply will be provided for your region.

More Info

The Bullet Blender® Field Model Enhancement

A fully portable, lightweight unit that will allow you to homogenize samples as you collect them. The Field Model contains an internal rechargeable battery, capable of 25 completer 5 minute runs of 6 tubes each between charging. This upgrade weighs only 9 pounds including the internal rechargeable battery pack, and fits in most backpacks.Equipped with a padded handle for easy carrying, this factory upgrade is available on models that use microcentrifuge tubes. Includes a vehicle charger for recharging the Field Blender on the road. Must be purchased with a microcentrifuge tube Bullet Blender, such as BBX24, BBX24W, BBX24B, or BBX24W.

- Battery provides over 2 hours of continuous use.

- Padded handle for easy transport

- Modified capacity of 6 microcentrifuge tubes to maintain performance when battery is low.

- Car power adapter included

The BIOBOX™ Bullet Blender®

The BioBox Bullet Blender is a homogenizer with an extra barrier of protection.This high-throughput homogenizer allows you to homogenize up to 24 samples simultaneously in separate screw-cap microcentifuge tubes, with additional protection against pathogens and other potentially hazardous samples. Full automation ensures that you get highly reproducible results, while the locking enclosure, kept under negative pressure, provides an extra level of protection unmatched by other automated homogenization systems.This is a factory installed enhancement, so the BBX24W or BBX24BW must be purchased at the same time. The BioBox and Bullet Blender units ordered with the BioBox are final sale only.

- Secondary enclosure for containing contaminants.

- Negative Pressure to ensure leaks are inward and contaminants do not escape.

- Interlocks to indicate that the secondary enclosure is closed and seal is intact.

- Transparent to visually confirm tube and sample integrity.

4 °C Cooling™ and Air Cooling™ in The Bullet Blender®

Gold models of the Bullet Blender homogenizers contain a 4 °C Cooling™ system. Fill the side compartment with dry ice. When the instrument is running, cold air will blow past the sample tubes. Air circulation will adjust according to homogenization conditions, maintaining the samples near 4 °C. If dry ice is not used, ambient temperature air blows past the sample tubes. This Air Cooling™ reduces the heating of the samples.

Blue and Storm model Bullet Blender homogenizers are equipped with Air Cooling™, which draws air into the Bullet Blender, keeping your samples near ambient temperature. This feature is particularly effective if your samples are sensitive to heat and you are using your Bullet Blender in a refrigerator or a cold room. The Air Cooling™ is also useful for preventing the inside of your Bullet Blender unit from heating up if you are running several consecutive homogenization cycles. Air Cooling™ is an option on the microtube models and standard on the 5 mL and the 50 mL tube models.

FAQ

>4 °C Cooling™:

What is 4 °C Cooling™? 4 °C cooling uses a compartment filled with dry ice to keep samples near 4 °C. When the instrument is in operation, cold air from the compartment is drawn into the instrument, cooling the samples. Some users prefer to pre-cool their Bullet Blenders before use. To pre-cool, fill the compartment with dry ice and run the instrument with no tubes inside for 5 minutes or until the "4 °C" light comes on.

Which models have 4 °C Cooling? The 4 °C cooling feature comes on Gold models of the Bullet Blender— BB24-AU which homogenizes samples in 1.5 mL microcentrifuge tubes and BB50-AU which homogenizes samples in 50 mL tubes.

Which models have 4 °C Cooling? The dry cooling feature comes on Gold models of the Bullet Blender— BB24-AU which homogenizes samples in 1.5 mL microcentrifuge tubes and BB50-AU which homogenizes samples in 50 mL tubes.

How much dry ice do I need to use 4 °C Cooling? It takes at least 2 lbs of dry ice for the instrument to achieve maximum cooling. We recommend filling the chamber with 3 lbs of dry ice- depending on how heavily the instrument is used, this should keep samples at 4 °C for an entire day of homogenization.

Why is the 4 °C light not lighting up on my Bullet Blender Gold unit? Frost from condensation may be blocking the air passage. Remove the inner dry ice compartment and gently agitate it or replace the ice.

What will happen if I operate my Bullet Blender Gold unit with no dry ice? When there is no dry ice in the compartment, you should operate the instrument with the lid of the dry ice compartment open so that the instrument can operate using Air Cooling™.

>Air Cooling™

What is Air Cooling™?

Most models have Air Cooling™. These models exchange air with their surroundings; they do not have refrigeration units. Air Cooling™ effectively draws cold air into the instrument if you are using the Bullet Blender® in a cold room or a refrigerated cabinet. Air Cooling™ is also useful if you're running several sample cycles in a row or if your samples are extra sensitive to heating up. Normally, the samples in the Bullet Blender® only heat up a few degrees and stay quite cool. However, if you're running a second batch of samples soon afterward, they will heat up a little more because the Bullet Blender® is starting out slightly warmer. The Air Cooling™ keeps the Bullet Blender® cooler so that the first batch of samples heat up a little less and subsequent batches are kept just about as cool as the first batch.

Which models have Air Cooling™?

The Air Cooling™ feature comes on all models of the Bullet Blender® except the standard Bullet Blender for microcentrifuge tubes (BBX24). Gold models not running with dry ice can be run in Air Cooling™ mode if the dry ice compartment lid is left open to enable air exchange.

Use and Operation:

Before using, please see our General Guidelines for Use (link missing)

How is the Bullet Blender different from other high-throughput homogenizers on the market? The Bullet Blender is similar to other Bead Mill Style homogenizers in that it processes each sample in its own tube using homogenization beads. Therefore, there is no chance of cross-contamination and there are no parts that need cleaning after each sample. A unique feature of the Bullet Blender is the way it agitates the sample tubes. Other bead-mill homogenizers vigorously shake the sample tubes, which requires a great deal of energy. The large motors required tend to make these homogenizers large and expensive: many are 2-3 times the cost of the Bullet Blender. The Bullet Blender, on the other hand, uses a patented striking method to agitate tubes. This energy-efficient approach requires a much smaller motor and avoids the need to clamp tubes down, so the Bullet Blender is smaller, lighter, and less expensive than competitors' equipment while working just as well. The rapid oscillation of the tubes in the stream of rapidly flowing air causes convective cooling, so sample heating is minimal, especially in models with Air Cooling or 4ºC Cooling. The Bullet Blender can also be used in a cold room, unlike many of the other instruments on the market.

What types of tubes can be used?

Microcentrifuge models: The Bullet Blender® Storm works with our RINO tubes or 1.5 mL Eppendorf® Safe-Lock tubes. The Bullet Blender® and Bullet Blender® Blue work with standard polypropylene snap-cap microcentrifuge tubes though we strongly recommend 1.5 mL or 2.0 mL Eppendorf® Safe-Lock tubes. When using 2 mL tubes in the the Bullet Blender® or the Bullet Blender® Blue we recommend using a minimum of 2 tubes per homogenization cycle. The obsolete screw cap models (BBX24W and BBX24BW) use Axygen® and Corning® 1.5 mL screw cap tubes.

5 mL tube models: The Bullet Blender® Blue 5 units work with 5 mL Axygen® brand screw top transport tubes. We also offer a model that works with Eppendorf® 5 mL tubes. As these are different in size than the Axygen tubes, these 5 mL models can handle one type of tube or the other, but not both in the same instrument.

50 mL tube models: The Bullet Blender 50-DX and 50-AU (DX and Gold models) work with 50 mL skirted (self-standing) polypropylene tubes, such as Axygen® brand or Corning® brand. The slightly hazy polypropylene tubes are tougher and resist the striking better than the clearer tubes, which might crack at higher speeds. Use high quality tubes, rather than bargain brand tubes which are not as strong.

How do you set the Bullet Blender® to mix, disrupt, or homogenize different types of samples? You can adjust the speed and the duration. Adjusting the speed affects how firmly the balls will strike the sample tubes, while adjusting the duration affects the total number of impacts. Homogenizing tough tissue requires longer durations at full speed, while mixing or cell dissociation requires lower speeds.How easy is it to operate the Bullet Blender®?

Simply place up to 24 sample tubes in the holders, set the desired duration and speed, and push start. All the samples will be processed simultaneously, without any chance of cross contamination.

How much sample can be homogenized in each microcentrifuge tube?

General tips: Tubes should be filled no more than 75% full (50% for 50 mL tubes). The air volume inside the tube is critical to allow the sample to be ground up inside the tube, so if the tube is overfilled, the efficiency of the homogenization is reduced. A very high ratio of buffer to sample can also impair homogenization. A good general rule of thumb is to use one volume of beads and two volumes of buffer per volume of sample.

For microcentrifuge model Bullet Blenders, we recommend using 10-300 µg of tissue. Less than 10 µg will work, but it requires careful attention to the amount of beads and volume of homogenization buffer. Samples larger than 300 µg are not recommended. The 5 mL tubes can hold up to about 1 mL of sample tissue or pelleted cultured cells, and a total of 3.5 mL of sample, buffer, and beads combined. The 50 mL tubes can hold up to about 3.5 mL of sample tissue or pelleted cultured cells, and a total of 20 mL of sample, buffer, and beads combined. Note that for most wet organ tissue 1 mL≈1 g.

Do sample tubes need to be placed symmetrically?

No. There are no restrictions as to which holes to place your sample tubes in, however you may get better results if you space them apart as evenly as possible.

How do you retrieve the sample from the tubes?

After the Bullet Blender® stops, simply remove the tubes and draw off the liquid with a pipet. If a clear lysate is desired, the sample may be centrifuged to clarify the lysate prior to use in your applications. Tubes may be centrifuged with the beads in them for ease of handling.

Which beads should I use?

The protocols page contains suggested beads, speeds, and durations for processing many types of tissues and cells. The two basic rules for bead selection: (1) use denser beads for tougher samples, and (2) use beads of a comparable size to the size of your samples to maximize the effectiveness of collisions between beads and samples. For example, if you wanted to lyse mammalian cells with a soft membrane, use small glass beads. If you want to homogenize larger pieces of tough tissue, use large steel beads. "UFO" beads are excellent for homogenizing fibrous or resilient samples. You can also contact our technical support staff if you have any questions.

I am trying to process tough samples in the Bullet Blender® and the homogenization is incomplete. How can I improve my results?

There are several ways that you can increase the homogenization of your samples.

- Examine the shape of your samples- long thin samples will homogenize faster than cube-shaped or round samples.

- Try cutting your samples into smaller pieces.

- Ensure your tubes are not overloaded.

- If you are running many samples at once in the standard or Blue models of the Bullet Blender (BBX24 or BBX24B), try running fewer tubes at a time. If a sample is extremely tough (e.g. mouse femur) you may only be able to achieve complete homogenization with 2-4 tubes at a time.

- If you are using the BB50-DX or BB50-AU, make sure that all of the sleeves are removed except for the sleeves containing tubes.

I previously owned another bead mill homogenizer. Can I use the same protocols that we developed for the other homogenizer with the Bullet Blender®?

No, the mechanism of action is different from all other homogenizers on the market. Our patented striking technology makes the Bullet Blender both highly efficient and effective. If you use another product's protocol with the Bullet Blender, you are very likely to experience different results. Please use one of our established protocols, or empirically determine a protocol that works best for your samples. We also offer free protocol development services.

Is it possible to homogenize tissue that has been frozen in liquid nitrogen?

It is possible to homogenize tissue that was frozen in liquid nitrogen. Immerse the frozen tissue in cold buffer and allow it to thaw, then treat it as you would any other sample. If the tissue was dried before it was frozen, you can pulverize the tissue by homogenizing with beads only (no buffer), then adding the cold buffer and running again to complete the homogenization. You cannot homogenize "wet" tissue while it is still frozen, as it will effectively be a block of ice and homogenization efficiency will be very poor.

What is the "Key-Switch Lock Out" option for Bullet Blenders?

This key switch option incapacitates the electronics, preventing others from operating your Bullet Blender. Thereby, others are discouraged from working in your area, using your supplies, and upsetting your experiments.

Homogenizer Overview

Manual Methods - Mortar & Pestle and Dounce homogenizers:

Manual methods of homogenization use mechanical force applied by hand in order to crush tissue and cells. The most common form of homogenizers are mortar and pestle homogenizers, in which a hard, blunt object (the pestle) is pressed against the container holding the sample (the mortar). In most cases, the pestle is a small plastic object and the microcentrifuge tube or other tube containing the sample acts as the mortar. Plastic mortars are very inexpensive, however because the entire homogenization is performed by hand, human error is high, reproducibility is low, homogenization effectiveness is very poor, and repeated homogenization becomes very tedious and is very slow. The use of battery-operated pestle holders, which spin the pestle to produce additional shear force on the samples and assist in homogenization, make the method slightly less tedious and slightly more effective.A slight improvement on this method is the dounce homogenizer. In a dounce system, the mortar and pestle come bundled and are specially crafted for use with each other. This ensures a tighter fit and improves homogenization efficiency, however cross-contamination becomes an issue since the dounce must be thoroughly washed between each sample. Buying multiple dounces is an option, however quickly becomes expensive. Furthermore, a dounce system is still slow, tedious, and highly irreproducible due to human error.

Rotor-Stator homogenizers:

Also known as mechanical shear homogenizers, these units use shear force, usually produced by spinning blades, to homogenize samples. Laboratory blenders that are similar in design to the blenders one would have in their kitchen do exist, however they are not practical for most applications and represent a small minority of rotor-stator homogenizers. The vast majority of rotor-stator homogenizers are probe-style instruments which contain smaller motor-driven blades (the "knife") at the end of a rotor shaft. Liquid enters the rotor-stator and the knife creates a shear force to disrupt the samples. These types of instruments are far more powerful than manual homogenization, and can be used with cells in suspension. Various models of varying probe size and power are designed to handle different sizes and toughness of samples. Metal probes require cleaning; however some units have plastic probes which are disposable. Some are hand-held, but many can be mounted for hands-free use, helping to reduce human error somewhat. Fully automated systems are available which largely eliminate human error but these are often an expensive solution to single-sample homogenization, costing upwards of $5000 or more. Automated systems which can homogenize multiple samples also exist, however these are very expensive, often $10000 or more. Within a reasonable budget, one is usually limited to single-sample systems. Due to the rapid mechanical shearing action inside the samples, a significant amount of heat can build up with extended use. Since this heat is generated within the sample itself, it is not well controlled by cooling methods. Lastly, because the sample container needs to be open and the rotor stator creates rapid blending action, operation of a rotor-stator can become messy and aerosols may be a problem if working with hazardous substances.

Ultrasonic homogenizers:

Ultrasonic homogenizers, or sonicators, use an electronic generator to send waves of high-frequency mechanical energy through a transducer to a "horn", which then rapidly vibrates. This vibration creates a rapid forming and collapsing of small bubbles within the system, a process known as cavitation. Similar to rotor-stators, most sonicators are designed to homogenize one sample at a time, and are available at a wide range of powers and sizes for different sized samples. Automated systems are also available for sonication, with some high-end high-throughput systems reaching well into the tens of thousands of dollars. Simple, lower-powered systems are usually available for under $1000, however these systems are not suitable for rapid homogenization of multiple samples. Most often used for cell culture, sonicators are also not well suited for tearing through tough tissue, as the rapid cavitation simple cannot provide enough force, nor is it optimal for large amounts of any tissue. Sonicators are, however, the best homogenization devices for breaking apart small subcellular organelles. The main drawback of sonication is the thorough denaturation of protein due to cavitation, and the addition of a large amount of heat, making high-power sonicators a poor choice for temperature-sensitive assays including most RNA work. Sonicators also use expensive probes that must be polished and carefully cared for to prevent erosion or pitting, which can greatly decrease the effectiveness of the sonicator.

High-pressure homogenizers:

High-pressure homogenization, where a press is used to lyse cells, is an old method applied mostly to single-celled, non-filamentous microorganisms. In pressure homogenizers, such as the once popular but discontinued French Pressure Cell ("French Press"), cell suspensions are forced through small channels under high pressure. This creates a large pressure drop and strong shearing forces to lyse cells. Lysis is effected by the pressure, flow rate, and temperature of the system, and a recycling flow is often implemented to subject the suspension to the pressure drop and shear force multiple times. Steel plates or rings placed near the low-pressure exit of the channels, upon which the cells collide, is sometimes implemented and also aids in disruption. High-pressure homogenizers exist which can process many thousands of liters of cell suspensions per hour, and their throughput for the homogenization of single-celled organisms is unmatched. These systems are generally unable to homogenize tissue without prior dissociation, and attempting to do so will merely clog the device. High-pressure homogenization also generates a significant amount of heat, usually requiring pre-cooling of both the machine and the sample to mitigate. Most systems have also been frequently criticized for being messy to use, and all require thorough cleaning after use both to keep the unit sterile and to prevent cross-contamination. The systems are expensive, usually well over $10,000, and are also large and extremely heavy. For these reasons, researchers are moving away from pressure cell homogenization in favor of other methods. Some, however, remain loyal due to the excellent cell lysis capabilities.

Bead Mill homogenizers:

Bead mill homogenizers use the rapid agitation of beads to tear through tissue and lyse cells. The homogenization beads tear through tissue to dissociate it and collide to create high-energy areas which lyse cells. Many bead-mill systems are high-throughput and can handle tough tissue about as well as a rotor-stator. Bead-mill systems are hands-free and automated, and most can homogenize a large amount of samples in a few minutes or less. A distinct advantage of a bead-mill system is afforded by the use of different sizes of beads. Larger beads are less efficient at disrupting small particles, while smaller beads are very efficient. By varying the bead size and thoroughness of the homogenization (via alteration of the time and speed settings), one can homogenize small cells, nuclei and other subcellular organelles, and other small particles, or leave organelles or even whole cells intact. This makes bead mills far more versatile than other systems. Because the systems are fully autoamted and the samples remain contained, there is extremely high reproducibility and virtually no risk of cross-contamination.The drawback to most bead mill systems is the tradeoff between power and price - most cheaper systems cannot handle tougher samples, and most systems capable of homogenizing tough tissue are prohibitively expensive. Furthermore, most bead mill systems require a lot of power and therefore generate a lot of heat, requiring liquid or dry ice cooling. However, all of these drawbacks are addressed in the Bullet Blender®.

What sets the Bullet Blender® apart?

The Bullet Blender® uses a patented, simple yet powerful striking technology in which "bullets" spin around on spokes and rapidly strike the tubes to agitate the homogenization beads. This hub-and-spoke system is far more efficient than the traditional shaking system, allowing us to use a smaller motor and therefore generate far less heat while still being able to homogenize tough samples, such as muscle, carcinoma, and roots. The heat generated is so small that even with repeated operation our simple Air Cooling™ system is enough to keep the samples within a just few degrees of the ambient temperature (and the Bullet Blender can be used in a 4 °C room). Also, because the device has just one moving system it is far more reliable than other devices - the less components a system has, the less of a chance there is that something will break. Furthermore, because using a Bullet Blender allows you to homogenize in standard tubes, the cost of operating the Bullet Blender is uniquely low. This, combined with a price 3-4x lower than other high-performance, high-throughput bead mills, creates a unique value that allows researchers access to top-quality performance at a reasonable price.

Literature

Brochure on the Bullet Blender

(PDF)Brochure on the Bullet Blender Gold

(PDF)Bullet Blender Homogenization Presentation

(PDF slides)Bullet Blender Users Guide - Tips and Tricks

(PDF)How to use the Bullet Blender

(PDF) Bullet Blender® Homogenizer - Protocols The Next Advance Bullet Blender Homogenizer Protocols

Bullet Blender® Homogenizer - Protocols The Next Advance Bullet Blender Homogenizer Protocols Note 99: Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS

Note 99: Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS Note 100: Volatile and Semi-Volatile Profile Comparison of Whole Versus Cracked Versus Dry Homogenized Barley Grains by Direct Thermal Extraction Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS

Note 100: Volatile and Semi-Volatile Profile Comparison of Whole Versus Cracked Versus Dry Homogenized Barley Grains by Direct Thermal Extraction Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS

| Part No. | Description | Picture | Quantity In Stock |

Price EA |

Order |

|---|---|---|---|---|---|

| Standard BBX24 | |||||

| BBX24 | BULLET BLENDER - DISRUPT OR HOMOGENIZE CELLS AND TISSUE; UP TO 24 SAMPLES IN MICRO-CENTRIFUGE TUBES AT A TIME. ALSO USE IT TO MIX SAMPLES. INCLUDES: BULLET BLENDER; OPERATORS MANUAL; SPATULA; TUBES (10 ML) OF BEADS IN 7 SIZES AND MATERIALS. |  |

DISCONTINUED | --- | --- |

| BBX24CE | BULLET BLENDER W/CE CERTIFICATION - SIMILAR TO BBX24 BULLET BLENDER WITH UPGRADED ELECTRONICS AND CE CERTIFICATION. | DISCONTINUED | --- | --- | |

| Blue BBX24B | |||||

| BBX24B | BULLET BLENDER BLUE - SIMILAR TO BBX24; WITH THE ADDITION OF AIR COOLING. |  |

DISCONTINUED | --- | --- |

| BBX24BCE | BULLET BLENDER BLUE W/ CE CERTIFICATION- SIMILAR TO BBX24B WITH UPGRADED ELECTRONICS AND CE CERTIFICATION | DISCONTINUED | --- | --- | |

| Storm BBY24M | |||||

| BBY24M | Bullet Blender Storm Homogenizer for 24 samples in microcentrifuge tubes. More powerful motor. Includes starter kit of beads, scoops and tubes. With air cooling. |  |

DISCONTINUED | --- | --- |

| BBY24MCE | BULLET BLENDER STORM-CE HOMOGENIZER FOR 24 SAMPLES IN MICROCENTRIFUGE TUBES. MORE; POWERFUL MOTOR. INCLUDES STARTER KIT OF BEADS, SCOOPS AND; TUBES. WITH AIR COOLING | DISCONTINUED | --- | --- | |

| Gold BB24-AU | |||||

| BB24AU | Bullet Blender Gold Homogenizer. 24 samples in microcentrifuge tubes. More powerful motor. Cooling to maintain 4C sample temperature. Includes starter kit of beads, scoops and tubes. |  |

DISCONTINUED | --- | --- |

| BB24AUCE | BULLET BLENDER GOLD-CE HOMOGENIZER. 24 SAMPLES IN MICROCENTR. TUBES. MORE POWERFUL; MOTOR. COOLING TO 4 C SAMPLE TEMPERATURE. INCLUDES; STARTER KIT OF BEADS, SCOOPS | DISCONTINUED | --- | --- | |

| 5 Blue BBX5MB | |||||

| BBX5MB | BULLET BLENDER BLUE 5 SIMILIAR TO BBX24B, FOR UP TO 12 SAMPLES IN 5ML TUBES. | DISCONTINUED | --- | --- | |

| BBX5MBCE | BULLET BLENDER BLUE 5 WITH CE CERTIFICATION - SIMILIAR TO BBX5MB WITH UPGRADED ELECTRONICS AND CE CERTIFICATION. | DISCONTINUED | --- | --- | |

| 5 Storm | |||||

| BBY5M | Bullet Blender Storm 5 Homogenizer for 12 samples in 5 mL tubes. Includes starter kit of beads, scoops and tubes. With more powerful motor and Air Cooling. |  |

DISCONTINUED | --- | --- |

| BBY5MCE | BULLET BLENDER STORM 5-CE HOMOGENIZER FOR 12 SAMPLES IN 5ML TUBES. INCLUDES STARTER KIT; OF BEADS, SCOOPS AND TUBES. WITH MORE POWERFUL MOTOR AND AIR; COOLING. UPGRADED | DISCONTINUED | --- | --- | |

| BBY5E | Homogenizer for 12 samples in 5mL snap-cap tubes. Includes starter kit of beads, scoops and tubes. With more powerful motor and Air Cooling. | DISCONTINUED | --- | --- | |

| 50-DX | |||||

| BB50DX | Bullet Blender 50-DX Homogenizer for 8 samples in 50 mL tubes. Includes starter kit of beads, scoops and tubes. |  |

DISCONTINUED | --- | --- |

| BB50DXCE | BULLET BLENDER 50-DX-CE HOMOGENIZER FOR 8 SAMPLES IN 50ML TUBES. INCLUDES STARTER KIT; OF BEADS, SCOOPS AND TUBES. | DISCONTINUED | --- | --- | |

| 50 Gold | |||||

| BB50AU | Bullet Blender 50 Gold Homogenizer for 8 samples in 50 mL tubes. Cooling to maintain 4C sample temp. Includes starter kit of beads, scoops and tubes. |  |

DISCONTINUED | --- | --- |

| BB50AUCE | BULLET BLENDER 50 GOLD-CE HOMOGENIZER FOR 8 SAMPLES IN 50ML TUBES. COOLING TO MAINTAIN 4C; SAMPLE TEMP. INCLUDES STARTER KIT OF BEADS, SCOOPS AND TUBES. ; UPGRADED | DISCONTINUED | --- | --- | |

| Options | |||||

| FBBX | FIELD UNIT UPGRADE BULLET BLENDER FIELD UNIT UPGRADE. FACTORY UPGRADE TO ENABLE BBX24 TO; BE POWERED OFF ECHARGEABLE BATTERY FOR FIELD USE. MUST ORDER WITH | DISCONTINUED | --- | --- | |

| EWBBX | EXTENDED WARRANTY - EXTEND WARRANTY TO 4 YRS WITH PRIORTY ON REPAIRS. | DISCONTINUED | --- | --- | |

| BBX6F | BULLET BLENDER FIELD BULLET BLENDER FOR USE IN THE FIELD. INCLUDES RECHARGEABLE; BATTERY. SIMILAR TO BBX24, BUT ONLY HOMOGENIZES UP TO 6 SAMPLES; AT A TIME. INCLUDES | DISCONTINUED | --- | --- | |

| * Call for availability. | |||||

|

|

|||||

Bullet Blender® Homogenizer - Protocols The Next Advance Bullet Blender Homogenizer Protocols

Bullet Blender® Homogenizer - Protocols The Next Advance Bullet Blender Homogenizer Protocols Bullet Blender Beads Next Advance Bullet Blender Homogenizer Bead Overview and Prices

Bullet Blender Beads Next Advance Bullet Blender Homogenizer Bead Overview and Prices Bullet Blender® Accessories Everything you need to operate your Next Advance Bullet Blender

Bullet Blender® Accessories Everything you need to operate your Next Advance Bullet Blender Note 99: Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS

Note 99: Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS Volatile and Semi-Volatile Profile Comparison of Whole vs. Dry Homogenized Wheat, Rye and Barley Grains by Direct Thermal Extraction GC/MS