- ▶

- Heaters/Source

- ▶

- Agilent Heaters and SensorsMass Spectrometry, Scientific Supplies & ManufacturingScientific Instrument Services 5973 Source Heater Tamper Resistant Allen Wrench 5973/5975 Quad Sensor 5985 Source Heater Assembly Agilent Interface Heater Assembly 5971 Interface Heater

- ▶

- TD

- Software

- ▶

- TD Software (This Page)

Description

- Windows software to control your SIS thermal desorption system (TD5 or AutoDesorb).

- Optionally fully integrated with Agilent ChemStation or MassHunter and other systems.

- Configures TD methods, performs thermal desorption runs, and monitors system status.

- Free with your thermal desorption system.

Integration with Agilent ChemStation/MassHunter

The SIS Short Path Thermal Desorption systems (models TD-5 and AutoDesorb) are fully integrated with the Agilent ChemStation software (Figure 1). The thermal desorption (TD) windows are loaded when the ChemStation software is started. The entire GC or GC/MS process as well as the desorption process is started from the ChemStation windows. The Agilent ChemStation windows are used for the GC and MS operation as well as sample information and the TD windows are used for thermal desorption method setup and for thermal desorption process monitoring during sample analysis. Thermal Desorption Methods and Operation Methods are developed in the TD windows and saved into the Agilent ChemStation Method. Methods can be changed between subsequent samples to provide different desorption parameters for different samples or the same method can be used for all samples. For example, a separate high temperature bakeout or blank method can be setup and run between samples to assure the system is clean for the next sample.

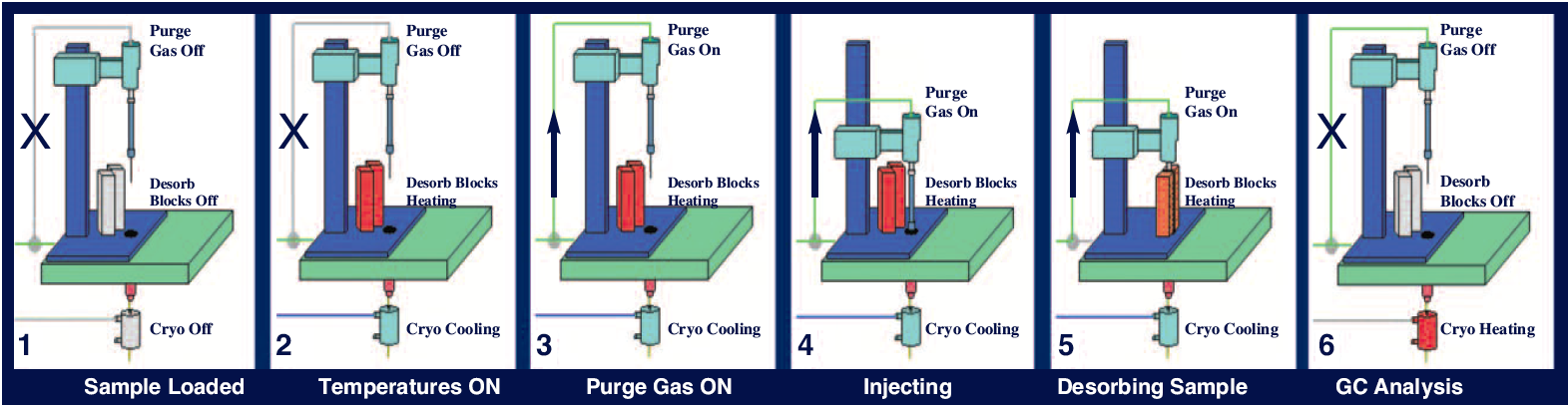

Figure 1 - The TD software display consists of 3 separate windows in the Run mode to monitor the thermal desorption System Status.

The TD software is designed to be graphical and easy to use. Sample information need only be entered once. For example, all data such as sample name and vial number are entered into the Agilent ChemStation sample run window or the sequence run window for the analysis of samples. This data is then automatically transferred to the TD windows when the sample is loaded, and then used in all sample logs and reports that are generated.

Software Windows

The TD software provides for the visualization and control of all the thermal desorption operations including sample purging and injecting times, desorption temperatures and times, GC start times and Cryo-Trap heating and cooling parameters. A user-friendly graphical interface displays the pictorial as well as digital status of the thermal desorption system operation and GC Cryo-Trap operation. Changes made to the thermal desorption methods can be saved to the Agilent ChemStation Method. All the thermal desorption setup and operational parameters are displayed on four graphics Windows screens. Other screens are available for system setup and for setting system limits.

Figure 2 - Thermal Desorption Status Window

The first of these windows is the Thermal Desorption Status Window (Figure 2). This screen displays graphically and digitally the current status of the TD system. The graphic display visually demonstrates the mechanical operation of the thermal desorption system as it occurs. The informational digital display lists the current thermal desorption system conditions including sample name and vial number (which were entered in the Agilent ChemStation window), the desorption and cryo-trap temperatures, GC inlet pressure (this pressure value is used to detect for system leaks) and the status of the GC gas valving systems.

Figure 3 - Temperature Settings Screen

The second screen is the Temperature Settings Screen (Figure 3). Thermal desorption Temperature Method setup is done here as well as monitoring the current status of the thermal desorption block heaters and cryo-trap temperatures. On the bottom of this screen are entered the operational parameters for the thermal desorption system and the cryo-trap. Up to three levels of multi-step temperature ramping and temperature holding can be programmed for the desorption heater blocks. Both the heating and cooling parameters for the 2 inch Cryo-Trap are entered in this chart. The system electronics automatically detects if a Cryo-Trap is installed and if it is it can detect if it is a CO2 or LN2 version of the Cryo-Trap. Depending on the type of Cryo-Trap, the system limits are automatically put into the program and the software programs the Cryo-Trap for the accurate cooling and heating of the trap. This method can then be saved to the Agilent ChemStation method file and used for the analysis of subsequent samples. The graphics display visually shows the temperature profiles for the thermal desorption blocks and the cryo-trap on a time scale. When the desorption run is started, the actual temperatures of the desorption blocks and cryo-trap are plotted on this graphic.

Figure 4 - Time Settings Screen

The Third screen is the Time Settings Screen (Figure 4). The thermal desorption System Time Method setup is done here as well monitoring the current status of Purge Gas Time, Injection Time, Desorption Time, Cryo-Trap cool and heat times and the GC Start Run Time. On the bottom section of this window are entered the times for the various thermal desorption and cryo-trap processes. The GC start time can be at set at anytime from the time of injection until after the desorption process is complete. The graphic display shows the relative times of each of these events. During the actual desorption process, a time bar shows the actual time position of the thermal desorption process. The total desorption time is shown as was calculated from the desorption block heater program set up in the previous screen. In addition this screen indicates that the CO2 version of the Cryo-Trap was detected by the system as described for the previous screen.

Figure 5 - Sample Log Screen

The fourth screen is the Sample Log Screen which maintains a log of all samples analyzed by the thermal desorption system (Figure 5). A detailed log is maintained of each sample analyzed including the vial number and time the analysis was started as well as any error messages for problems that may have occurred during the sample run. This report can be saved and printed out to report the samples that were analyzed.

Figure 6 - The System Limits Screen

The System Limits Screen enables the user to establish parameters which should not be exceeded by the system operator (Figure 6). These limits include the maximum temperature for the desorption blocks and cryo-trap, maximum sample gas pressure, and maximum times for purging, injecting and desorbing samples. This minimizes the possibility of a user inadvertently entering erroneous data when setting up a method. If bad data such as a desorption temperature of 800 degrees C or a desorption time of 600 minutes are entered, the data will not be accepted and the operator will be prompted to correct his method parameters.

The AutoDesorb System was first introduced at PittCon 99 in Orlando, FL in March 1999, with TD software designed and developed by David Manura at SIS. It includes multi step desorption heater block programming, a LN2 as well as CO2 Cryo-Trap with automatic detection, a prefilter cartridge in the connecting tube to assure clean pure carrier gas for purging samples, a new desorption tube needle design which permits leak-tight sealing of the needles with finger tight connections, and expanded graphics in the system software. The software is designed to work with the Agilent (HP) 5890/6890/7890 GC's, most versions of ChemStaion (and recently MassHunter), and Windows 10/8.1/8/7/Vista/XP/2000, and older versions supporting 2000/NT/98/95. It may optionally be used stand-alone (not integrated to the MS data system), particularly for non-Agilent GC's.

Software Releases

The latest version of the SIS Thermal Desorption Software is 1.2.0 (2014-02-26).

- sistd-1.2.0-20140226.exe - Contact us to request a download key.

- SIS TD Software Manual 1.2.0

Version 1.2.0 Compatibility: Win 2000 - Win 10 (latest version; use older version for older operating systems) MS ChemStation B.xx - E.xx GC ChemStation A.xx - B.xx MassHunter B.xx SIS TD-5 and SIS AutoDesorb 2000