Description

![]()

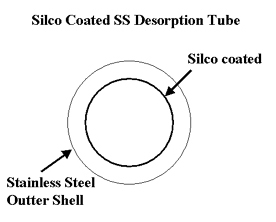

The Silco Coated Stainless Steel Desorption Tubes are available in two inside diameters, i.e. 3 mm and 4 mm. Each tube is 4.0 inch long by 1/4 inch outside diameter and is threaded on both ends. After conditioning and sample loading, the ends of the tubes are fitted with stainless steel caps with seals to maintain the integrity of the medium and sample. PTFE and Viton® seals can be used in the caps to make the seal. These same threads on the Desorption Tube also provide the means of connecting the Desorption Tubes to the desorption connector tube and the injecting syringe needle utilizing one of the 4 types of seals.

3.0 mm desorption tubes are easier to seal than 4.0 mm tubes.

Features

- Strong stainless steel (S.S.) outer shell

- Silco Coated ID

- S.S. caps with seals to prevent contamination

- S.S. needles attach to tubes for injection

- Available in 3.0 and 4.0 mm ID

- Reusable with proper cleaning and conditioning

Tubes are serialized for proper identification of samples. The Silco Coated Stainless Desorption Tubes have an inside diameter of 4.0 mm. Each tube is 4.0" long by 1/4" diameter and is threaded on both ends. The inert Silco coating protects your samples during thermal desorption to minimize analyte breakdown due to reaction with metal surfaces. After conditioning and sample loading, the ends of the tubes can be fitted with stainless steel caps with seals (sold separately) to maintain the integrity of the sample until analyzed. PTFE seals are normally used to seal the caps to the desorption tubes. These same threads on the desorption tube provide the means of connecting the desorption tubes to the connector tube and for the attachment of the desorption tube needle. All tubes are serialized for accurate identification of tubes and samples. These tubes are also available cleaned, silyated and washed. Desorption Tubes are available empty or they can be packed by SIS.

This thermal desorption tube is used in applications where a larger I.D. is required (I.D. - 4.0 mm). The silco coating on the inside of the thermal desorption tube still protects your sample by eliminating the direct contact of samples with the metal surface and thereby minimizes the thermal reactions of analytes with the interior of the desorption tube. The larger I.D. of this tube permits almost twice the amount of sample or thermal desorption resin to be contained inside the desorption tube. All tubes are serialized for accurate identification of tubes and samples. Tubes are available empty or can be packed

This is a lower cost thermal desorption tube that can be used in many applications where analytes are not thermally sensitive. These tubes are constructed of stainless steel with no coating on the walls. These tubes are currently available in 4.0 mm I.D, only. All tubes are serialized. Packing of these tubes is also available on special request.

Accessories

Tubes should be baked out prior to use.

Indicate # of packages Desorption tubes are supplied empty, without caps or seals. Tubes should be baked out prior to use.

For the AutoDesorb® Model 2000 Automated Short Path Thermal Desorption System

![]()

Theory of Operation

Thermal Desorption Tubes

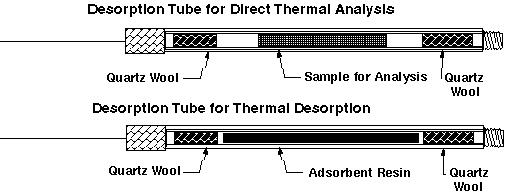

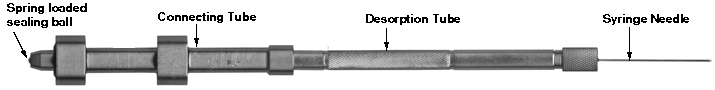

Figure 1 - Thermal desorption tube

Two types of desorption tubes are available for the SIS Short Path Thermal Desorption System (Models TD 1, 2, 3, 4 and 5) as well as the SIS AutoDesorb System. Our standard desorption tube is the 4.0 mm I.D. Silco Coated Stainless Steel desorption tube. This is the desorption tube that is normally recommended, since it contains an inert Silco coating to protect your samples from catalytic thermal breakdown. We also have 4.0 mm I.D. tubes available without Silco coating stainless steel.

Figure 2 - Cross section of thermal desorption tube

Each desorption tube is 4.0" long by 1/4" diameter and is threaded on both ends. These same threads on the desorption tube provide the means of connecting the desorption tubes to the connector tube and for the attachment of the desorption tube needle. All tubes are serialized for accurate identification of tubes and samples.

Figure 3 - Desorption Tubes can be packed with an adsorbent resin or with solid matrix samples

Samples to be analyzed are collected on desorption tubes containing an adsorbent resin such as Tenax® TA or activated carbon. Alternatively, samples of small size (1 to 500 mg) can be packed directly into the desorption tube and subjected to direct thermal extraction. The thermal desorption tubes can be obtained both empty or packed with a wide variety of thermal desorption resins. These thermal desorption tubes can be reused hundreds of times which brings the cost of sample containers down to pennies per sample.

Figure 4 - Desorption tube and needle connected to connecting tube

When ready for analysis, the thermal desorption tube is attached to the connecting tube and the desorption needle is attached to the other end of the desorption tube. This connecting tube is the adaptor that enables the desorption tube to be attached to the AutoDesorb carousel for thermal desorption analysis. The top of the connecting tube contains a spring loaded ball to seal the desorption tube and sample until the actual thermal desorption process begins.

Figure 5 - Loading of the Thermal Desorption tubes into the AutoDesorb Carousel

The thermal desorption tube is then loaded in to the AutoDesorb system carousel. Up to 12 desorption tubes can be loaded into the carousel. Tubes can be continuously loaded and unloaded during the running of the sample sequence. During the thermal desorption process, each desorption tube is checked for leaks. If a problem occurs with the sample such as a pressure leak or system parameter problem, the sample is unloaded and resealed and a report of the error is indicated in the sample log table. The sample integrity is maintained, which enables the error to be corrected and the sample reanalyzed.

Needles and Seals

Needles for the AutoDesorb System

Figure 6 - 2 Piece Needle Assembly for the AutoDesorb System

In the AutoDesorb System, the needle serves as the transfer line for the introduction of the sample into the Gas Chromatograph. This "short path" for sample transmission is the key advantage of the Short Path Thermal Desorption technology which minimizes sample decomposition, eliminates system contamination and provides for the maximum delivery of samples to the GC. This 2 piece needle has been specifically designed for the AutoDesorb system. This design will permit the sealing of the needles and connecting tube to the desorption tube with just a finger tight twist connection. Vespel® seals (sold separately) are used to make the leak tight seal. Double seals (as in the TD5 System) are not needed with this system. The needles are of the side port design to eliminate coring of the GC septa and are 35 mm long. The needles are available in plain stainless steel and now also in Silco coated steel to eliminate any metal surface in contact with your samples. These needles and seals can also be used in the Older models of the Thermal Desorption system (Models TD3 and TD-4).

Seals for the AutoDesorb System

A single one-piece Vespel® seal is used to make the leak tight seal between the desorption tube and the needle as well as the desorption tube and the connecting tube. These seals permit the finger tight sealing of the desorption tube to the system. Wrenches and tools are not required. Seals can be used up to 450 degrees C. The double seals used in the TD5 are not used in the AutoDesorb system

Connecting Tubes and O rings for the AutoDesorb System

Figure 7 - Assembly of desorption tube with needle, connecting tube and 1 piece Vespel seals

The AutoDesorb System is shipped with 12 Connecting tubes, however the user may wish to obtain additional spare connecting tubes. These connecting tubes are designed exclusively for the AutoDesorb system and require both an O Ring (purchased separately) and a Vespel Seal (purchased separately).

Figure 8 - Cross section of connecting tube

Built into each connecting tube is a trap filter. This filter is packed with 40 milligrams of Carbotrap and is used as a final filter to assure clean carrier gas is passed through you sample. The trap filter can be cleaned by baking out in the tube conditioning oven

| Part No. | Description | Picture | Quantity In Stock |

Price EA |

Order |

|---|---|---|---|---|---|

| 786002 | Silco Coated SS Desorption Tube, empty, 4.0 mm I.D., serialized |  |

4 | $65.25 | |

| 786003 | Stainless Steel Desorption Tube, empty, 4.0 mm I.D., serialized |  |

0*Standard lead-time for non-stock items is approximately two weeks depending on the item. | $29.50 | |

| 781006 | SS Cap for Desorption Tube, solid |  |

221 | $7.95 | |

| 781007 | S.S. Desorption Tube Cap with 0.040in hole for conditioning Silco Coated tube |  |

113 | $9.95 | |

| 781122 | Aluminum Funnel for loading desorption tube |  |

3 | CALL | |

| * Standard lead-time for non-stock items is approximately two weeks depending on the item. | |||||

|

|

|||||

Prepacked, Conditioned Desorption Tubes All packed Thermal Desorption Tubes are Silco™ Coated S.S. tubes.

Prepacked, Conditioned Desorption Tubes All packed Thermal Desorption Tubes are Silco™ Coated S.S. tubes.

Purge and Trap Stainless Steel Purge Heads

Purge and Trap Stainless Steel Purge Heads  Thermal Desorption Sample Loader

Thermal Desorption Sample Loader  Short Path Thermal Desorption Accessories Supply Kit

Short Path Thermal Desorption Accessories Supply Kit  Seals for SIS Thermal Desorption Tubes

Seals for SIS Thermal Desorption Tubes  Needles for the Short Path Thermal Desorption System

Needles for the Short Path Thermal Desorption System  SIS Purge and Trap System

SIS Purge and Trap System  Thermal Desorption Sample Collection System

Thermal Desorption Sample Collection System  24 Tube Conditioning Oven for Thermal Desorption Tubes

24 Tube Conditioning Oven for Thermal Desorption Tubes  Thermal Desorption Conditioning Oven - 6 Tube

Thermal Desorption Conditioning Oven - 6 Tube  Aluminum Funnel for Loading Packings into Desorption Tubes

Aluminum Funnel for Loading Packings into Desorption Tubes