Description

Seals are utilized in a variety of locations in the Short Path Thermal Desorption Unit. These seals are used (1) in the Desorption Tube Stainless Steel Caps, (2) in the Desorption Tube Syringe Needle, (3) at the connection of the Desorption Tube to the connector tube in the Desorption Unit, (4) to form seals in the Desorption Tube Conditioning Oven, (5) to form seals in the Desorption Tube Sampling Oven, (6) to form seals in pumping systems for sampling systems utilizing the Desorption Tubes, and (7) in other accessories to which the Desorption Tube is to be connected and a leak tight connection is required.

Seals are used on the inside of the Desorption Tube Stainless Steel Caps to provide a contaminate free surface and to form an air tight seal between the Desorption Tube and the cap. These seals are important to maintain the integrity and prevent the contamination of conditioned Desorption Tubes before being subjected to sample collection as well as after sample collection. The preferred seals for this application are normally PTFE washers (S.I.S. part # 781004).

Seals are used at the top end of the Desorption Tube against the connecting Tube (Top Sealing Washer) and at the bottom end of the Desorption Tube next to the needle cap (Needle Sealing Washer), when the Desorption Tube is installed in the Desorption Unit. It is imperative that these seals are leak tight even at pressures up to 30 P.S.I. for the proper operation of the Desorption Unit and to provide for the complete delivery of desorbed sample into the GC injection port. The seals used to seal the needle cap assembly to the Desorption Tube (Needle Sealing Washer) normally have a small I.D. to seal snugly around the needle shaft and minimize metal surface exposure to the samples being analyzed. The Top Sealing Washers have a larger I.D. to prohibit seal collapse and hindrance of the gas flow through the Desorption Tube. When soft materials such as graphite are used for the top seals, a metal tube is inserted inside the center hole in the washer to prevent the graphite from closing and restricting gas flow (part # 781015). This same seal is also utilized in Desorption Tube conditioning handles and Desorption Tube adaptors to provide good seals particularly at elevated temperatures.

Indicate # of units. Viton and PTFE have 10 washers per unit, the rest have 1 washer per unit.

Parts

Graphite seals are physically soft but have excellent sealing properties and temperature limits and are recommended for most applications with the Desorption System. The graphite seals have good sealing properties when tightened finger tight, have a fairly good life, and provide for the highest temperature without contamination of the system by foreign matter.

Graphitized Vespel® seals contain 40% graphite and physically are harder than graphite seals but with lower temperature limits. They require slightly more force to form a good seal in the Desorption Unit. Normally about 1/16 turn past finger tight will form a good seal. Since these seals are harder than graphite, they hold their shape better, have a longer life, and are easily removable.

Viton seals are easy to use and remove. However, their main limitation is the bleed that may be seen at higher temperatures, much like the bleed seen from GC septa. In addition, the constant turning of the Desorption Tube when screwed into the fittings tends to abrade and wear these seals, causing leaks after 10 or 12 sample runs.

PTFE seals have temperature limitations like the Viton seals, but are good general seals for lower temperature applications. They have good sealing characteristics, good abrasion resistance, and are usable to about 230 degrees C. At temperatures above this they tend to flow and then are quite difficult to remove from the fittings.

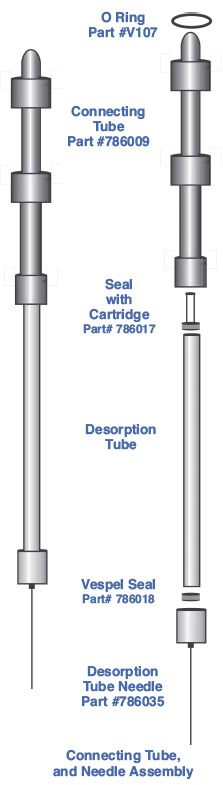

The double seals on both ends of the desorption tube as shown above are recommended. The Graphitized -Vespel seal should always be against the desorption tube due to its good abrasive and wear characteristics. The graphite seal should be against the needle and connecting tube due to graphites excellent flowing and sealing properties. This combination will provide optimum performance, life and leak free seals. Tighten all tubes as needles, finger tight then 1/8 turn past finger tight with the pliers. This will maximize seal life and provide for consistent leak free seals.

Specs

| Properties of Sealing Materials | |||

|---|---|---|---|

| Material | Max. Temp. | Sealing Properties | Abrasion Properties |

| Viton | 250 degrees C | Good | fair |

| PTFE | 230 degrees C | Good | good |

| Graphite | 450 degrees C | Excellent | poor |

| Graph Vespel® | 350 degrees C | Good | good |

Seals

Seals for the AutoDesorb™ System

A single one-piece Vespel™ seal is used to make the leak tight seal between the desorption tube and the needle as well as the desorption tube and the connecting tube. These seals permit the finger tight sealing of the desorption tube to the system. Wrenches and tools are not required. Seals can be used up to 450 °C. The double seals used in the TD5 are not used in the AutoDesorb system.

A single one-piece Vespel™ seal is used to make the leak tight seal between the desorption tube and the needle as well as the desorption tube and the connecting tube. These seals permit the finger tight sealing of the desorption tube to the system. Wrenches and tools are not required. Seals can be used up to 450 °C. The double seals used in the TD5 are not used in the AutoDesorb system.

Connecting Tubes

Connecting Tubes and ‘O’ Rings for the AutoDesorb System The AutoDesorb™ System is shipped with 12 Connecting tubes, however the user may wish to obtain additional spare connecting tubes. These connecting tubes are designed exclusively for the AutoDesorb system and require both an ‘O’ Ring (purchased separately below) and a Vespel Seal (purchased separately as listed above). Built into each connecting tube is a trap filter. This filter is packed with 40 milligrams of Carbotrap and is used as a final filter to assure clean carrier gas is passed through you sample. The trap filter can be cleaned by baking out in the tube conditioning oven

| Part No. | OD (in) | ID (in) | Thickness (in) | Cap Seal | Top Seal | Needle Seal | Acc Seals | pkg of | Quantity In Stock |

UOM | Price | Order | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 781003 | Viton Washers | ||||||||||||

| 0.21 | 0.08 | 0.06 | Yes | Yes | Yes | Yes | 10 | DISCONTINUED | PK | --- | --- | ||

| 781004 | PTFE Washers | ||||||||||||

| 0.21 | 0.12 | 0.06 | Yes | Yes | Yes | Yes | 10 | 89 | EA | $9.75 | |||

| 781015 | Graphite Top Sealing Washer | ||||||||||||

| 0.21 | 0.06 | 0.06 | No | Yes | No | Yes | --- | 534 | EA | $14.50 | |||

| 781017 | Grap Vesp Top Sealing Washer | ||||||||||||

| 0.22 | 0.06 | 0.06 | No | Yes | No | Yes | --- | 0†Standard lead-time for non-stock items is approximately two weeks depending on the item. | EA | $11.00 | |||

| 781018 | Grap Vesp Needle Seal Washer | ||||||||||||

| 0.22 | 0.04 | 0.06 | No | No | Yes | Yes | --- | DISCONTINUED | EA | --- | --- | ||

| 786017 | VESPEL SEAL W/CARTRIDGE FOR THE AUTODESORB SYSTEM | ||||||||||||

| --- | --- | --- | --- | --- | --- | --- | --- | 0‡Lead time for this non-stock item is approximately 5 days. | EA | $27.00 | |||

| 786018 | SEAL-AUTODESORP NEEDLE GRAPH/VESPEL | ||||||||||||

| --- | --- | --- | --- | --- | --- | --- | --- | 0†Standard lead-time for non-stock items is approximately two weeks depending on the item. | EA | $10.50 | |||

| 786017 | VESPEL SEAL W/CARTRIDGE FOR THE AUTODESORB SYSTEM | ||||||||||||

| --- | --- | --- | --- | --- | --- | --- | --- | 0‡Lead time for this non-stock item is approximately 5 days. | EA | $27.00 | |||

| 786910 | SEAL TOOL FOR AUTODESORB | ||||||||||||

| --- | --- | --- | --- | --- | --- | --- | --- | 0†Standard lead-time for non-stock items is approximately two weeks depending on the item. | EA | $55.75 | |||

| 786009 | CONNECTOR TUBE AUTODESORB | ||||||||||||

| --- | --- | --- | --- | --- | --- | --- | --- | 0†Standard lead-time for non-stock items is approximately two weeks depending on the item. | EA | $145.00 | |||

| V107 | VITON O RING .206 X .103 | ||||||||||||

| --- | --- | --- | --- | --- | --- | --- | --- | 8 | EA | $0.59 | |||

|

* Call for availability. † Standard lead-time for non-stock items is approximately two weeks depending on the item. ‡ Lead time for this non-stock item is approximately 5 days. | |||||||||||||

|

|

|||||||||||||

Needles for the Short Path Thermal Desorption System

Needles for the Short Path Thermal Desorption System  Short Path Thermal Desorption Accessories Supply Kit

Short Path Thermal Desorption Accessories Supply Kit  Short Path Thermal Desorption Tubes

Short Path Thermal Desorption Tubes  Purge and Trap Stainless Steel Purge Heads

Purge and Trap Stainless Steel Purge Heads  Thermal Desorption Sample Loader

Thermal Desorption Sample Loader  24 Tube Conditioning Oven for Thermal Desorption Tubes

24 Tube Conditioning Oven for Thermal Desorption Tubes  Thermal Desorption Conditioning Oven - 6 Tube

Thermal Desorption Conditioning Oven - 6 Tube  SIS Purge and Trap System

SIS Purge and Trap System  Thermal Desorption Sample Collection System

Thermal Desorption Sample Collection System