- ▶

- Heaters/Source

- ▶

- Agilent Heaters and SensorsMass Spectrometry, Scientific Supplies & ManufacturingScientific Instrument Services 5973 Source Heater Tamper Resistant Allen Wrench 5973/5975 Quad Sensor 5985 Source Heater Assembly Agilent Interface Heater Assembly 5971 Interface Heater

- ▶

- LiteratureApplication Notes Adsorbent Resins Guide Mass Spec Tips SDS Sheets FAQ MS Calibration Compound Spectra Manuals MS Links/Labs/ Organizations MS Online Tools Flyers on Products/Services Scientific Supplies Catalog About Us NextAdvance Bullet Blender® Homogenizer Protocols Micro-Mesh® Literature Instrumentation Literature Agilent GC/MS Literature SIS News / E-Mail Newsletter NIST MS Database - Update Notifications

- ▶

- SIS News / E-Mail NewsletterJan 2021: Wiley 12 & NIST 20 Jun 2020: NIST 20 Release 2020 Aug 2017: NIST 17 Release 2017 May 2017: SIS at ASMS 2017 May 2017: NIST 17 Sep 2016: New Website Launch Aug 2016: IMSC 2016 Aug 2016: New Ion Transfer Tubes May 2016: ASMS 2016 May 2016: Agilent Dry Pump May 2016: Wiley Registry 11th February 2016: PITTCON 2016 February 2016: GC columns Dec 2015: GC Columns Special Sep 2015: SIS at AVS 2015 Jul 2015: Ion Transfer Tubes May 2015: SIS at ASMS 2015, thermal desorption poster barley, manufacturing Feb 2015: SIS at Pittcon 2015, TD, homogenizer Jan 2015: Save big on vacuum & MS products in 2015 Dec 2014: Gifts for your lab Nov 2014: NIST 14 and Wiley 10 mass spectral libraries Jun 2013: Thermal desorption on beer, ion transfer tubes & capillaries Apr 2013: Service kits for Waters MS Mar 2013: Bullet Blender® homogenizer, DigiVac vacuum gauge May 2012: Long Life Yttria Coated Filament Repairs Apr 2012: SIS rotary vane vacuum pump and filters Mar 2012: Imtakt HPLC columns, New Era syringe pump May 2011: NIST, SIMION, MS replacement parts Oct 2009: Lymtech sterile wipes, Ametek/Dycor leak detector filaments Sep 2009: Source heater/sensor for Agilent 5973/75, oil mist elements Older newsletters 1993-2009... Older What's New 1995-2001...

- ▶

- Older What's New 1995-2001...

- ▶

- 1/00 through 12/01 (This Page)

Posted 5/03/01

SIS at the ASMS meeting in Chicago - Annual SIS Ice Cream Hospitality Suite

SIS will be attending the ASMS meeting on May 27 to May 31, 2001 at the Hyatt Regency Hotel in Chicago. Stop by the SIS Booth during the meeting,

The Tradition Continues at ASMS

Once again we will be sponsoring our Ice Cream Sundae Hospitality Suite at the Atlanta room in the Hyatt Regency Hotel. We will be serving ice cream sundaes from approximately 7:30 p.m. until 9:30 pm, on Monday, Tuesday and Wednesday evenings. Both SIS and DeTech will be present in the SIS Hospitality Suite to answer your questions, discuss your current and future projects and to solicit your input as to how we can better serve your needs. So come on by and pay us a visit.

Posted 5/03/01

SIS Introduces "The Mass Spec Source" Internet Newsletter

The latest edition of the SIS Newsletter is now available on our Web site.

The SIS Mass Spec Source Newsletter is designed for the mass spec community. This newsletter is published 3 or 4 times per year by Scientific Instrument Services. Each issue contains a variety of articles relating to mass spectrometers and related instruments. Articles are written by the staff of Scientific Instrument Services, our suppliers and our customers. Topics for articles include the service and repair of mass spectrometers, techniques to improve the operation of the mass spectrometer, mass spec tools, software aids for the mass spectrometer and much more. Each issue also contains new products and services available from Scientific Instrument Services.

This is the first edition of the SIS Mass Spec Source Newsletter via our Web Site. We anticipate that we will send this communication out once every 2 months. In it we will keep you informed of news at SIS, trade shows that we will be attending, new products being introduced and promotions on products.

To receive your copy of this newsletter or to get on our mail list, please fill out our survey form.

You are being sent this newsletter, because you requested it on line from our SISWEB home page on the internet or because you filled out one of our survey forms. If you do not wish to continue to receive this newsletter, please respond to us via e-mail and request that we delete your name from our e-mail newsletter list.

Posted 4/01/01

SIS Continues to Expand its Facilities to Serve the Scientific Market

SIS is continuing to expand our facilities and staff to better serve the needs of the scientific community. In the past 6 months we have added a total of 5 new technical people to our shop facilities. This is a 25% increase in staff which brings our total staff size to 25 people.

SIS has made major efforts in the past year to expand our machine shop. We have added a new computer controlled 4 axis vertical machining center (CNC Mill) and a multi-axis Mori Seiki turning center (CNC Lathe) to the machine shop. We now have a staff of 3 full time machinists in the machine shop to operate this equipment. This new equipment permits us to machine parts and components for end users, OEM's as well as our own parts for the thermal desorption systems and probes we develop and market.

|

Our manufacturing begins with 3-dimensional Computer Aided Design (CAD) of parts and assemblies using CadKey software on a PC. These drawings are then downloaded to another PC with Computer Aided Machining software (CAM). The CAM software converts the CAD drawing into the CAM format which can then generate the tools and machining tool paths for the machining of the part on the CNC equipment. |

|

Next the tool paths and tool selection generated by the CAM software is downloaded to the CNC equipment for machining of the components. The correct tooling is automatically loaded by the automated tool loaders into the CNC machine. The feed and cutting speeds for the selected tools are determined by the software depending on the materials being machined and the part is machined to the required specifications with tolerances better than 0.002". Complex parts can be machined due to the 4 axis capabilities of the equipment. |

|

After the parts are manufactured they are cleaned in our new Crest Closed Loop Ultrasonic Cleaning system. This system uses no organic solvents, only water, for the cleaning process. The water is continually recycled through ion exchange resins and carbon filters to maintain its high purity. The parts to be cleaned are immersed in the high purity water at elevated temperature and ultrasonics are used to super clean the parts until; they are; totally free of any contamination. |

|

The result

is a high precision manufactured part at reasonable cost.

A number of brochures describing out machine and repair shop facilities and capabilities can be downloaded from our web site.

|

Posted 2/15/01

SIS Obtaining ISO Certification

SIS is in the process of obtaining ISO Certification. ISO is an international program to provide for quality and improved customer service in an organization. It is comparable to GLP in a laboratory. Companies that are certified must document all their procedures and processes, provide for inspection and high quality control for their products and strive for continued quality improvement and customer satisfaction.

We made a decision to pursue ISO Certification about a year ago in order to improve our quality control procedures, to improve customer service, to better document what we do and the way we do it, and to position the company to better serve the needs of the scientific community. We started the ISO Certification process about 3 months ago and are well underway in the process. We hope to achieve final certification in December of this year. We anticipate that you will see the impact of the changes that will occur as a result of this program.

Posted 3/03/01

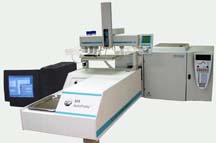

SIS AutoProbe™ introduced at PittCon 2001

SIS introduced the AutoProbe™ - an automated direct probe for the Thermo Finnigan TRACE™ mass spectrometer at this year's PittCon meeting in New Orleans.

|

The AutoProbe System is an Automated Direct Exposure Probe (DEP) for the Finnigan TRACE Mass Spectrometer System with a dual EI/CI source. The AutoProbe System injects samples directly into the MS source for mass spec sample analysis with no chromatographic separation. This permits samples to be analyzed in 3 minutes or less. The AutoProbe operates in the Thermo Finnigan Xcalibur™ MS Software environment and is fully integrated with the Xcalibur software, including system setup, methods setup, system operation and data storage. |

Applications of the direct probe technique include the screening of drug and pharmaceutical samples, quality control sample analysis, spot analysis of chemical reaction mixtures to monitor rates of synthesis, and the analysis of compounds which cannot be chromatographed. The AutoProbe System is used where high volumes of samples need to be analyzed quickly or it can be used in an "Open Access" environment where it can be operated by multiple users with minimal MS expertise.

Additional Details on the AutoProbe are available on our WEB site in the following files.

- AutoProbe General Description

- AutoProbe Console Description

- AutoProbe Software Description

- AutoProbe Specifications and Requirements

or download the 6 page color flyer on this product (505 K)

We currently have 4 application notes on the use and application on the AutoProbe.

Posted 2/03/01

Vacuum Pump Exhaust Filter System from SIS

|

SIS has recently introduced vacuum pump filter

kits for the rough pumps on your MS systems. These systems are recommended for

areas where it is not possible or practical to exhaust the MS vacuum pumps

outside the building. The filter system consists of two layered filters. The

first filter is an oil mist eliminator, which captures the heavy hydrocarbons

from the vacuum pump exhaust and returns these oils back into the pump. The

second stage of filtering, consists of a disposable charcoal trap, which traps

the more volatile organic compounds which are exhausted from the vacuum pump.

Four different Exhaust Filter Kits are now available for a large selection of

vacuum pumps.

We have complete Exhaust Filter Kits for specific models of vacuum pumps. Each kit includes a Koby Charcoal Trap, an Oil Mist Eliminator and all the fittings, centering rings, and clamps needed to complete the assembly of the filter system to the vacuum pumps. For additional details on the kit contents, descriptions and pictures, click onto the Kit # to link to the appropriate WEB page. |

Two Stage Filter Kits for most Vacuum Pumps are available from SIS.

- FK101 - Exhaust filter Kit for Alcatel Vacuum Pumps

- FK201 - Exhaust Filter Kit for Edward Pump Models E1M5/8, E2M3/5/8, RV3/5/8

- FK251 - Exhaust Filter Kit for Edward Pump Models E2M0.7, E2M1, E2M1.5

- FK251 - Exhaust Filter Kit for use on Agilent MSD Systems

We have three application notes on our web site with scientific studies demonstrating the effectiveness of these vacuum pump exhaust filters.

-

# 82 - Vacuum Pump Exhaust Filters, Part I - Two Stage Vacuum Pump Exhaust Filter System

-

# 83 Vacuum Pump Exhaust Filters, Part II - Oil Mist Eliminators

- # 84 Vacuum Pump Exhaust Filters, Part III - Charcoal Exhaust Traps

A four page flyer on vacuum pump filters can also be downloaded from our web site (478 K).

Posted 1/03/01

SIMION 3D version 7.0 Ion and Electron Optics Program

SIMION 3D version 7.0 is a PC based ion optics simulation program designed for instrument design of mass spectrometers and other ion optic instruments. At SIS we use this program to design new mass Spectrometer filaments and to study mass spec source design. Manufacturers of electron multipliers use this software to design their detectors and instrument designers use it to design new instruments and to maximize the sensitivity of the instruments. Use this powerful software to study ion source and detector optics in time-of-flight, quadrupole, ion trap and magnetic sector mass spectrometers in order to discover improvements that can be made to your instruments as well as to develop new instrument designs.

Part No. Description Price

SIMION7C SIMION Version 7.0 for Windows $475.00 Available from Scientific Instrument Services, Inc.

This is a new version of SIMION. There is no upgrade price.

NIST / EPA / NIH Mass Spectral Library

The latest version on NIST 98, Version 2.0 (January 2001) is now

available. Included with this release is the NIST/EPA/NIH Mass Spectral

Library (129,136 EI Mass Spectra of 107,886 Compounds with 107,829 chemical

Structures), Search Program Version 2.0, and AMDIS Mass Spec Interpreter

Version 2.1.

There are many new features in the program, some of the most important are:

- Structure searching - the program will now find all data based on its structural similarity. The searching can be done with either data from the NIST MS database, the user database or from a structure drawn in most chemical drawing packages.

- >Drag and Drop - Data can be dragged and dropped between window.

- User Library Structures - Present since version 1.6, but possibly new to some of you.

- Compare Views - There are a number of new ways that you can visually compare two spectra.

- Direct interaction with a number of chemical drawing packages - the clipboard can be used with some of them, most can be used by use of intermediate files.

The most important changes are in the overall user interface. The user interface should be easier to use and more conformant with normal Windows conventions.

Part No. Description Price

221010 NIST/EPA/NIH MS Library with Search Software and AMDIS $2000.00 221010UG* Upgrade of NIST/EPA/NIH MS Library with Search Software and AMDIS $750.00 Available from Scientific Instrument Services, Inc.

System requirements

The program is a true 32 bit program and thus requires Windows NT, 95,98 or 2000. This is a beta version of the installation, the program and the help file.

* For an Upgrade you must be the owner of a registered version of the program.

Posted 1/1/00

Heated Desorption

Sampling Chambers (Thermal Desorption Accessory)

The Heated Thermal Desorption Sampling

Chambers are used to contain large solid matrix samples for the purpose

of purging off the volatile and semi-volatile organics at elevated temperatures

and then trapping these analytes on thermal desorption tubes packed with

a variety of adsorbent resins. The samples collected are then analyzed

using the thermal desorption system in conjunction with a GC and/or GC/MS.

These systems are custom made on order and other chamber sizes can be constructed

according to your requirements.

Posted 3/15/99

GCQ Probe and Inlet

(Direct Probe and Probe Inlet system for the GCQ MS)

Scientific

Instrument Services has developed a new high temperature Direct Insertion

Probe (HT-DIP) for the ThermoQuest (Finnigan MAT) GCQ instruments. These

probes can be used from ambient temperatures up to 800o C with

a ballistic temperature ramping of over 700o C/min.

The

SIS Probe Inlet System for the GCQ Instruments has been redesigned to improve

the operation of the standard probe inlet and to increase seal life by

a factor of 50 or more. This is accomplished via the use of PTFE seals

with a greater vacuum sealing surface area.

See Also

- News - main index