- ▶

- Heaters/Source

- ▶

- Agilent Heaters and SensorsMass Spectrometry, Scientific Supplies & ManufacturingScientific Instrument Services 5973 Source Heater Tamper Resistant Allen Wrench 5973/5975 Quad Sensor 5985 Source Heater Assembly Agilent Interface Heater Assembly 5971 Interface Heater

- ▶

- VacuumPumps Oils/Greases Gauge & Tubes Hose & Accessories Filters - Oil/Charcoal Foreline Traps Gaskets & Material Fittings O-Rings Pump Parts (Precision Plus) Quality Monitor System Distillation Control Acoustic Enclosures For Rotary Vane Pumps Other Vacuum Accessories Digital Vacuum pressure regulator (VPC) Catalog Page F1

- ▶

- Filters - Oil/Charcoal

- ▶

- SIS™ All-In-One (This Page)

Description

Vacuum pumps are widely used for mass spectrometers and other vacuum equipment and can be a major source of indoor air contamination. It is recommended that vacuum pumps be vented outside the room or to a laboratory exhaust hood. However this is not always practical.

Air contamination by vacuum pumps originates from pump oils and oil contamination. Eventually these organics are exhausted from the pump into the laboratory air. These chemicals can present a serious environmental health problem in the laboratory.

The All-In-One Vacuum Pump Exhaust Filter System has proven to be effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps and helping maintain a safe environment.

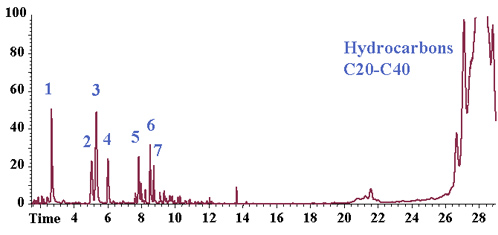

Without any exhaust filters, organic contaminant's from the pump oil and hydrocarbons from the pump oil exhausted out of the vacuum pump (bottom chromatograph).

During initial pump down or when using the gas ballast valve, oil vapors exhaust from the vacuum pump. The oil mist eliminator (Stage 1) traps the heavy hydrocarbons in this exhaust .

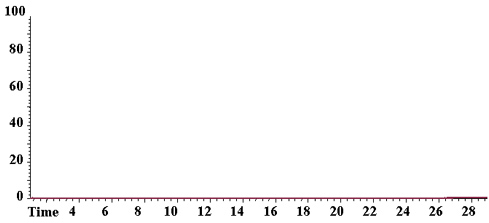

The charcoal trap (Stage 2) absorbs and traps the volatile and semi-volatile organics from the pump exhaust and prevents these organics from entering the laboratory environment (top chromatogram).

It is recommended that both filters in the All-In-One be replaced on a regular basis. The Carbon Filter (AC-10S) every 30 days and the Coalescing Filter (GL-915R) every six months. When the All-In-One filter is used on a vacuum pump exhaust port, the exhaust from the final stage of filtering has been shown the be cleaner than normal laboratory air.

Features

- 6.25" Total Height

- Purifies Vacuum Pump Exhaust Gases

- Provides for a Safe Laboratory Environment

- Low Cost

- Replaceable Elements

Stages

Stage 1 - Oil Mist Eliminator

Stage 1 - Oil Mist Eliminator

- Eliminates Pump Oil Fumes

- Returns Used Oil to Vacuum Pump

- Traps Particles to 0.3 microns

- Replaceable Coalescing Element

Stage 2 - Charcoal Filter

- Traps Organic Chemicals

- Replaceable Charcoal Element

Pump Exhaust with No Filtering

Pump Exhaust After Charcoal Trap

Kits

SIS All-In-One Pump Filter Kit for Adixen 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps.

SIS All-In-One Pump Filter Kit for Adixen 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps. SIS All-In-One Large Pump Filter Kit for Edwards 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps.

SIS All-In-One Large Pump Filter Kit for Edwards 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps. SIS All-In-One Small Pump Filter Kit for Edwards 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps.

SIS All-In-One Small Pump Filter Kit for Edwards 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps. SIS All-In-One Pump Filter Kit for Pfeiffer 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps.

SIS All-In-One Pump Filter Kit for Pfeiffer 6.25" high, low cost, combined oil mist eliminator and charcoal filter proven effective for removing volatile and semi-volatile organics from exhaust of vacuum pumps.

Replacement Elements

SIS Replacement Charcoal Filter Element The filter elements in the SIS Charcoal Filters are low in cost and disposable.

SIS Replacement Charcoal Filter Element The filter elements in the SIS Charcoal Filters are low in cost and disposable. SIS Coalescing Filter Replacement Element GL915R : -

SIS Coalescing Filter Replacement Element GL915R : -