- ▶

- Heaters/Source

- ▶

- Agilent Heaters and SensorsMass Spectrometry, Scientific Supplies & ManufacturingScientific Instrument Services 5973 Source Heater Tamper Resistant Allen Wrench 5973/5975 Quad Sensor 5985 Source Heater Assembly Agilent Interface Heater Assembly 5971 Interface Heater

- ▶

- Filaments

- ▶

- Long Life Yttria Coated SISAlloy® (Yttria/Rhenium Alloy) Mass Spec Filaments (This Page)

Description

Extended Filament Life for Mass Spectrometer Filaments.

SIS can now repair your filaments with yttria-coated SISAlloy® (yttria/rhenium alloy) wires and coils to replace the standard uncoated rhenium filaments. SIS repairs your filaments with our non-sagging rhenium alloy filament (SISAlloy®) material. We then electrically coat the filament with a thin film of yttria oxide. The result is a filament that does not sag due to the rhenium alloy filament material and the yttria oxide coated filament operates at a lower filament temperature to produce long life filaments. Using these yttria coated filaments, users have experienced filament lifetime increases of 2 to 3 times the life as compared to the standard uncoated rhenium filaments.

Features

Advantages of the New Rhenium Alloy + Yttria Coated Filaments

- Rhenium alloy filaments have less tendency to warp

- Yttria produces electrons at less filament current

- Filament runs cooler (up to 500 °C cooler)

- Filament lifetimes increase by 2 to 3 times

- Yttria coating protects the filament from oxidation

- Yttria is environmentally safer than Thoria

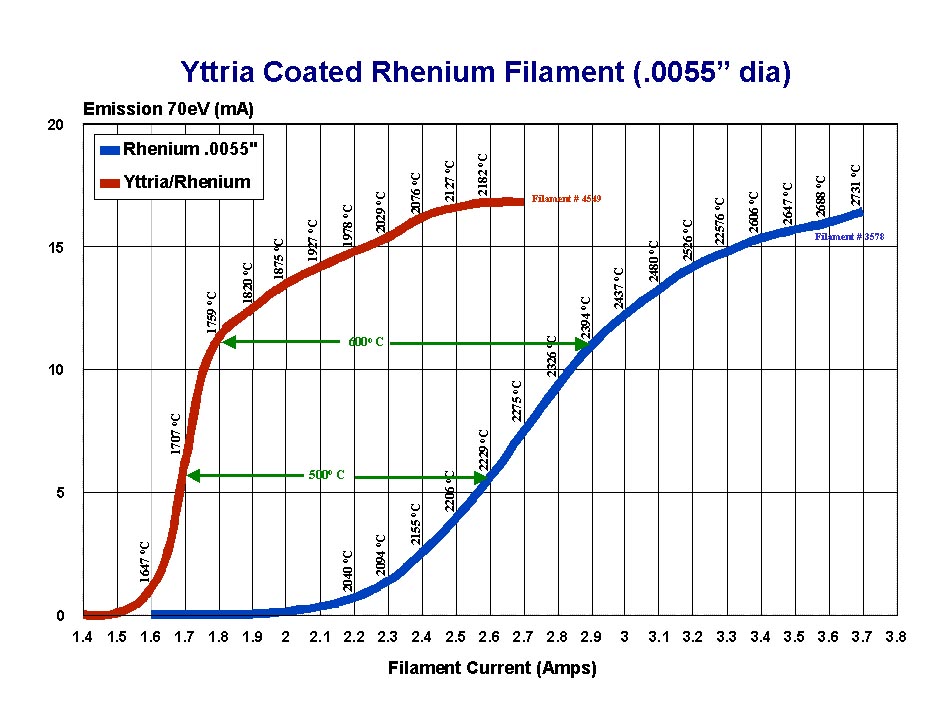

Yttria coated filaments have been used in the vacuum tube industry for more than 50 years. Yttria has a lower work function than rhenium or tungsten. Therefore these filaments emit electrons at lower filament current and therefore lower filament operating temperature as shown in the chart below. This results in increased filament life. In addition the thin oxide coating on the filament surface protects the filament wire from oxidation or chemical attack. This is why the yttria-coated filaments are used extensively for leak detector filaments.

Specs

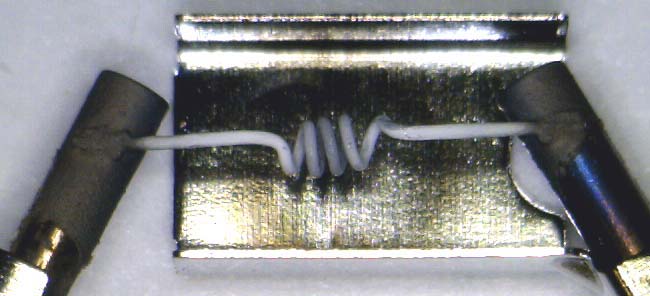

SIS can repair most styles of filaments using the combination of rhenium alloy material and yttria (yttrium oxide) coatings including the Agilent 4 coil filaments which are described in the study below. In this study we cycled the filaments ON and OFF in our testing system in order to determine its life. The Agilent 5973/5975/5977 filaments can be repairs using our SISAllow® filament coils which are then coated with yttria. The Agilent 5973/5975 filaments studied have demonstrated to typically last 2 to 3 times longer than standard plain rhenium filaments. In addition by using SISAlloy® instead of pure rhenium, filament warping is reduced thereby improving filament performance and lifetime. The pictures below demonstrate 3 times normal life from one of our studies in which the filament was cycled on and off. A pure rhenium filament lasts about 4,500 cycles in our studies before it burns out, but at 16,000 cycles the yttria-coated filament was still operating.

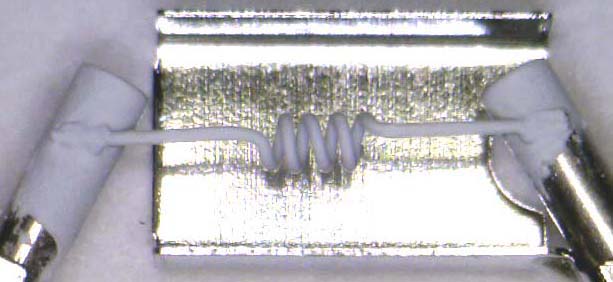

Yttria coated filament at start |

Yttria coated filament after 16,000 Cycles |

Caution: Do not touch the filament surface. The yttria coating is weak electrostatic coating onto the surface of the wire. The yttria coating is easily removed by touching or rough handling.

References

See Also

We also offer the older uncoated SISAlloy® yttria/rhenium filaments, if still desired. For non-standard wire shapes in which SISAlloy is not available, yttria-coated standard rhenium wire may be used.

Ordering Information

For ordering, see MS Filament Repair.

* SISAlloy® is a trademark of Scientific Instrument Services, Inc., patent US 2010/0277051 A1.