Home

- ▶

- Heaters/Source

- ▶

- Agilent Heaters and SensorsMass Spectrometry, Scientific Supplies & ManufacturingScientific Instrument Services 5973 Source Heater Tamper Resistant Allen Wrench 5973/5975 Quad Sensor 5985 Source Heater Assembly Agilent Interface Heater Assembly 5971 Interface Heater

- ▶

- VacuumPumps Oils/Greases Gauge & Tubes Hose & Accessories Filters - Oil/Charcoal Foreline Traps Gaskets & Material Fittings O-Rings Pump Parts (Precision Plus) Quality Monitor System Distillation Control Acoustic Enclosures For Rotary Vane Pumps Other Vacuum Accessories Digital Vacuum pressure regulator (VPC) Catalog Page F1

- ▶

- Distillation Control

- ▶

- Vacuum Pumps

- ▶

- Dry/Scroll Pumps

- ▶

- Adixen (Alcatel) ACP Series Compact Dry Roughing Pumps (This Page)

Focus on reliability, cleanliness and performance

ACP15 The ACP Series design incorporates the Adixen multi-stage Roots technology which is extensively field proven in the most difficult processes

ACP15 The ACP Series design incorporates the Adixen multi-stage Roots technology which is extensively field proven in the most difficult processes ACP28 The ACP Series design incorporates the Adixen multi-stage Roots technology which is extensively field proven in the most difficult processes

ACP28 The ACP Series design incorporates the Adixen multi-stage Roots technology which is extensively field proven in the most difficult processes ACP40 The ACP Series design incorporates the Adixen multi-stage Roots technology which is extensively field proven in the most difficult processes

ACP40 The ACP Series design incorporates the Adixen multi-stage Roots technology which is extensively field proven in the most difficult processes

Description

The ACP Series design incorporates the Adixen multi-stage Roots technology which is extensively field proven in the most difficult processes. The ACP Series pumps feature a frictionless pumping module, optimized for operation without internal lubricant. The result is no particle contamination, and no hydrocarbon backstreaming. Perfect for mass spec and many other applications.

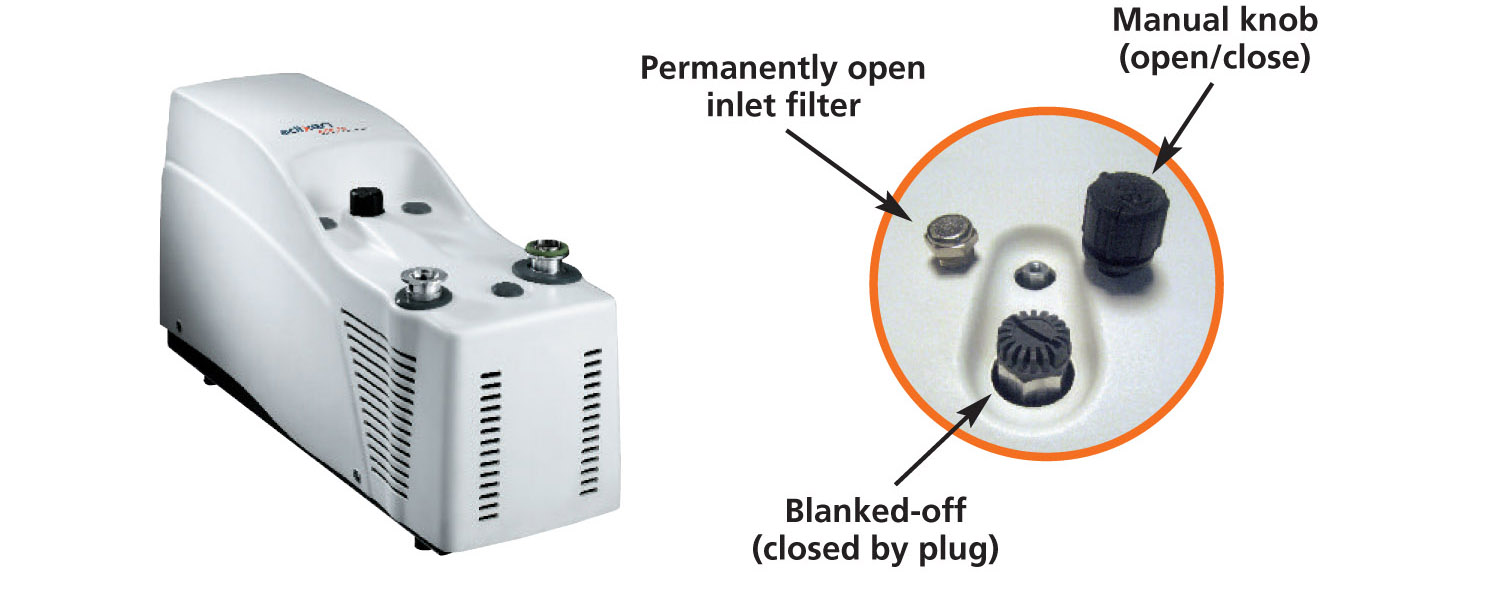

The pump is designed for applications that require pumping of clean (dust-free) and non-corrosive gases. Standard pumps are equipped with a gas ballast device to improve pumping of light gases and avoiding condensable vapors inside the pump.

Features

- No particle contamination

- Frictionless design.

- No wearing parts in the pumped gases path.

- No particle generation

- No hydrocarbon vapors backstreaming

- ACP series pumps are free of lubricant inside the pumping module.

- No hydrocarbon backstreaming

- Constant performance

- Constant internal clearances and constant rotational speed provide:

- Constant pumping speed

- Constant ultimate pressure

- High reliability

- Adixens expertise of dry multi-stage Roots pumps provides high reliability and ability to use in the most demanding applications

- Low maintenance costs

- No annual field service, the ACP series pumps require a completer overhaul only every 22,000 hours for the ACP 28/40, and 20,000 hours for ACP 15

- Condensable vapor ability

- With gas ballast ports and drainable silencers, ACP series pumps can handle high amounts of condensable vapors. (up to 100g/h of pure water vapor)

Applications

- Instruments

- Electron microscopes

- Surface analysers

- Leak detectors

- Mass spectrometers

- RGA

- R&D

- Particle accelerators

- High energy physics

- Laboratories

- Industry

- Lamp manufacturing

- Vacuum coating

- Cryo pumps regeneration

- Plasma cleaning

- Drying

- Load Lock

Specs

| Description | Units | ACP 15 | ACP 28 | ACP 40 |

|---|---|---|---|---|

| Peak Pumping Speed | m3/h CFM |

14 8.2 |

27 16 |

37 22 |

| Ultimate pressure w/o purge* | mbar torr |

3 x 10-2 2.2 x 10-2 |

||

| Ultimate pressure with open gas ballast* For SD version only |

mbar torr |

0.1 7.5 x 10-2 |

||

| Maximum continuos inlet pressure | mbar torr |

1013 750 |

||

| Maximum pure water vapor tolerance (measured) with open gas ballast (SD version) | g/h | 80 | 120 | 120 |

| Input Voltage | V | Single phase power: 100-230V +/- 10% - 50/60Hz Three phase power: 200-440V +/- 10% - 50/60Hz |

||

| Power Consumption* at ultimate pressure/ at atmosphere | W W |

450 550 |

700 1050 |

|

| Ambient Temperature | °C (°F) | 12 °C to 40 °C (54 °F to 104 °F) | ||

| Inlet Port | ISO-KF | DN25 | DN25 | DN40 |

| Exhaust Port | ISO-KF | DN16 | DN25 | DN25 |

| Helium Tightness | mbar.L/s | < 5 x 10-7 | ||

| Weight | kg. (lbs.) | 23 (51) | 30 (66) | 32 (70.5) |

| Overall Dimensions (L x W x H) |

mm (inches) mm (inches) |

514 x 190 x 270 (20.2 x 7.5 x 10.6) 497 x 190 x 266 (19.5 x 7.5 x 10.4) |

647 x 193 x 322 (25.4 x 7.6 x 12.6) 612 x 187 x 314 (24.1 x 7.36 x 12.3) |

|

** relative nitrogen pressure 300 mbar

Drawings

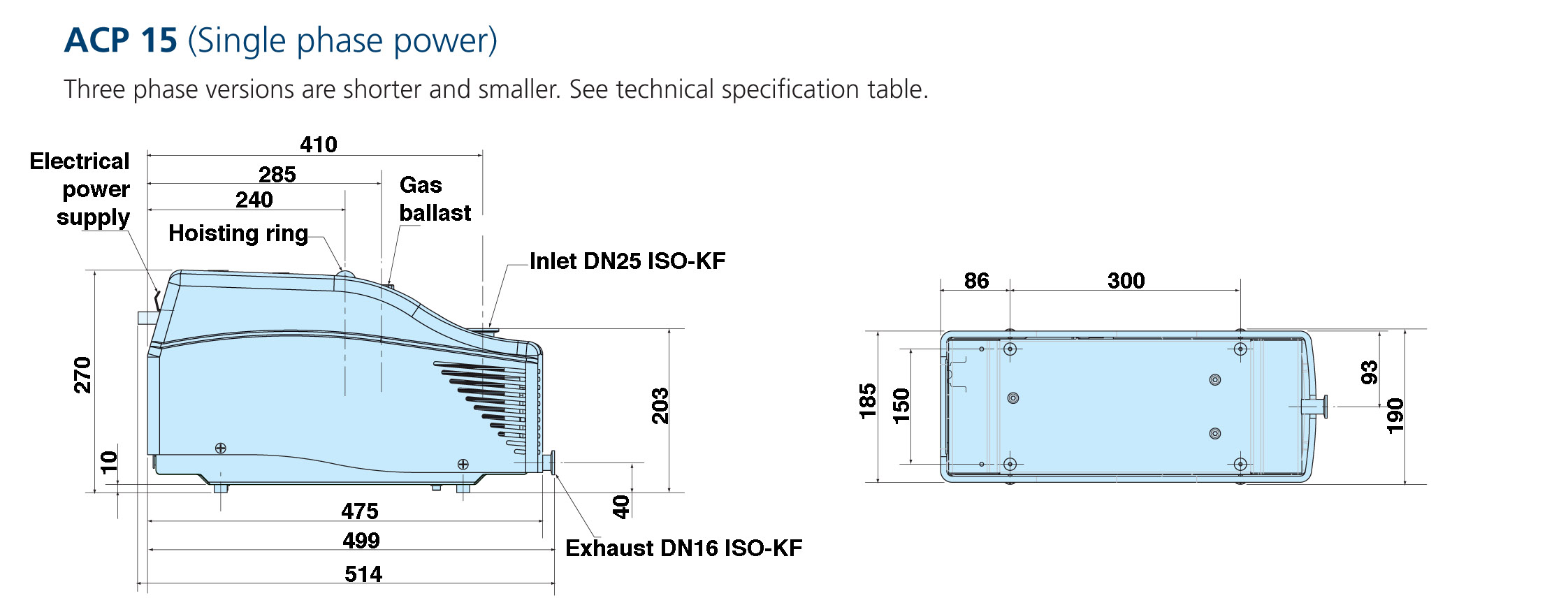

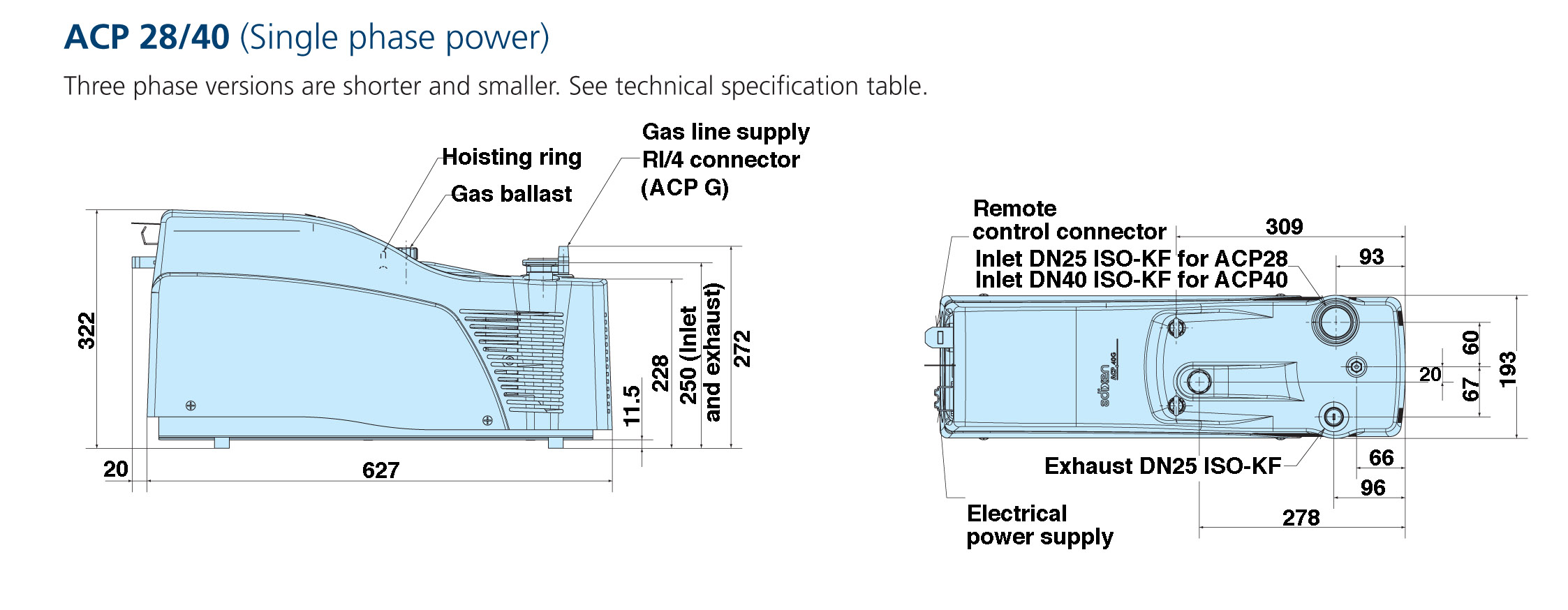

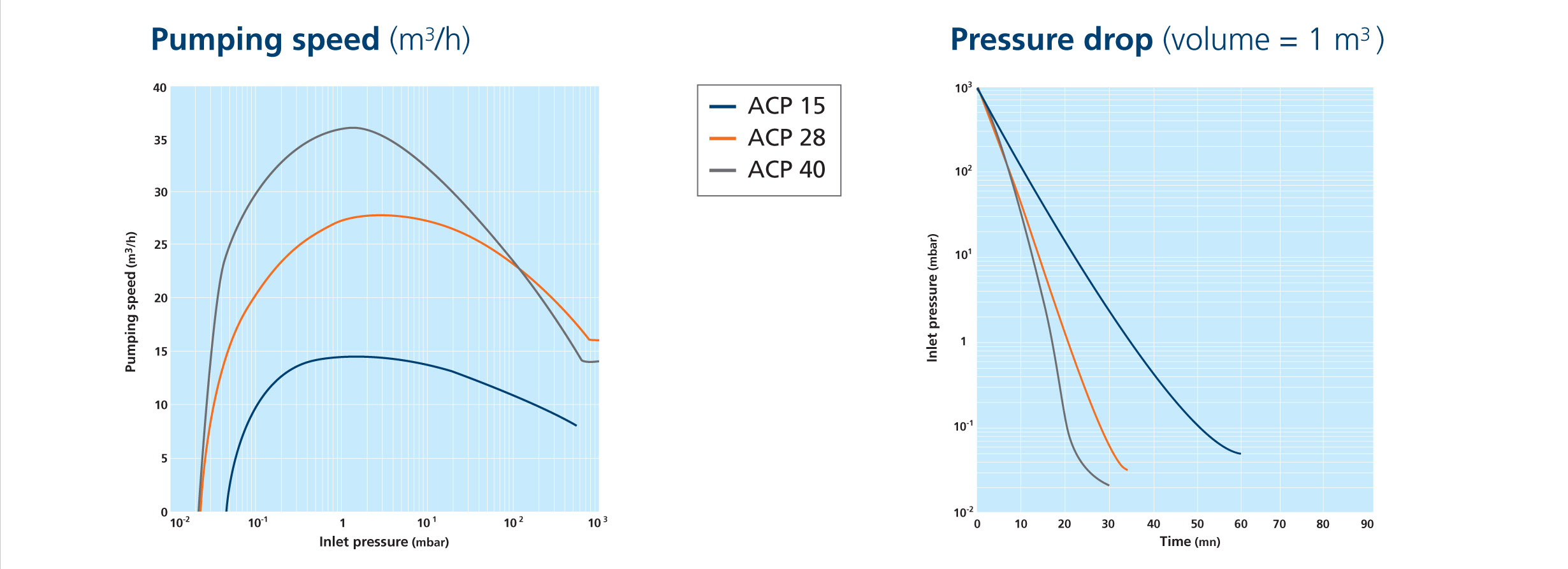

Pumping Curves Dimensions (mm)

Dimensions (mm)