Description

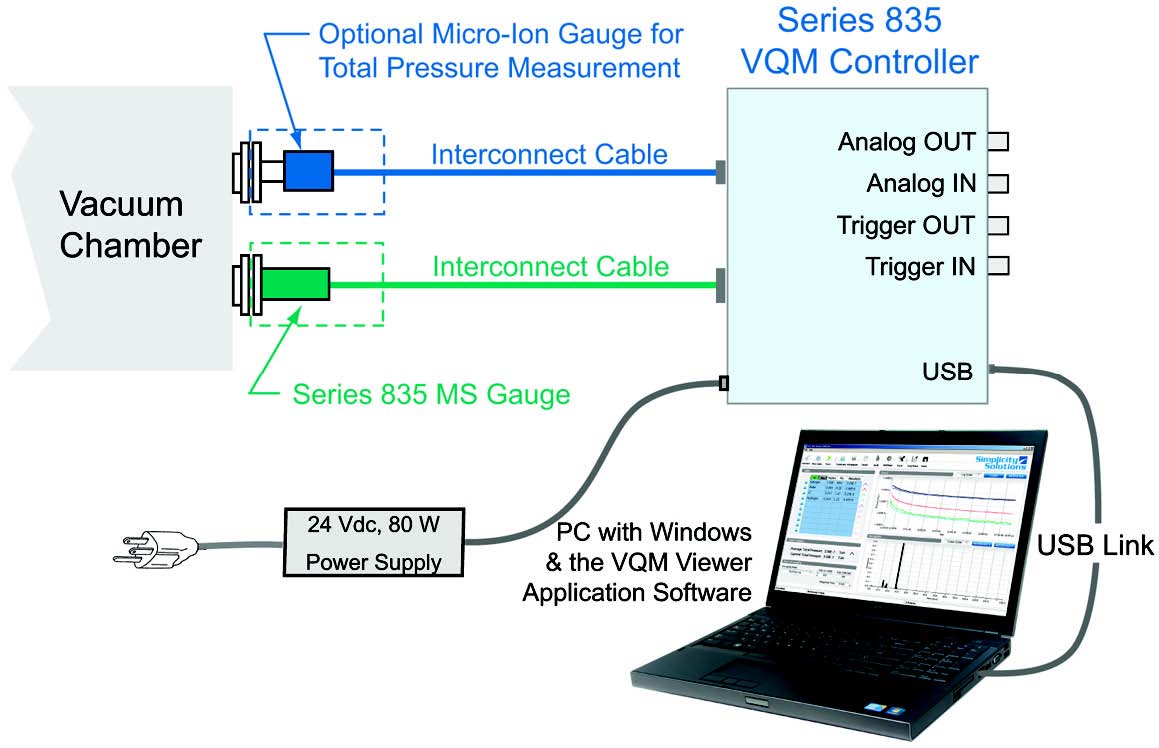

The Vacuum Quality Monitor (VQM™) by Granville-Phillips® combines the highest performance gas analysis technology with intelligent functional design that transforms complex measurement into actionable information. The 835 VQM system is the world’s fastest, lowest power, gas compositional analysis instrument with full data collection, spectral deconvolution, and data logging at 85 ms capture rates over the full 1–145 amu measurement range. Optionally, the VQM can monitor a full 1-300 amu at 120 msec rates. Partial scans can be selected to allow even faster scanning. In any vacuum system, it is critical to know the vacuum pressure.In many cases, it can be just as important to know the composition of the gases in the system.The 835 VQM is a mass spectrometer that operates from UHV to 10-5 Torr and accurately measures the gases in the vacuum chamber. The VQM system consists of an auto-resonant ion trap mass spectrometer gauge, a VQM Controller and VQM Viewer software that converts raw data to actionable information. The system is ratio metric, meaning that it determines the ratio of each gas to other gases in a vacuum chamber. It is usually coupled with a total pressure gauge to provide partial pressures of each gas which provides an indication of the quality of the vacuum in a chamber.

Out-of-the-box you see your 10 most prevalent gases, total pressure trending (with optional total pressure gauge), partial pressure trending, spectral display, data logging, data (screen) capture, gas fitting library for 10 gases, and leak check. The Controller and Gauge only requires a maximum of 15 watts to operate and offers the flexibility to remotely mount the 835 VQM Gauge using a cable from1 to 20 meters long.

Extras

Overview Video

A Revolutionary Approach

With the 835, Granville-Phillips expands on its revolutionary next generation mass separation technology based on the electrostatic ion trap which:

- scans more than 20 times faster

- requires 80% less power

- calibrates dramatically faster

- accurately represents low masses

- significantly smaller than legacy quadrupole or magnetic sector technologies

835 VQM Technology and Uses

Autoresonant ion trap mass spectrometer technology represents an entirely new way of mass selectively ejecting ions from an electro-static ion trap. The 835 VQM mass spectrometer gauge is natively a ratio metric measurement device that provides detailed compositional analysis of a gas mixture.

Theory of Operation

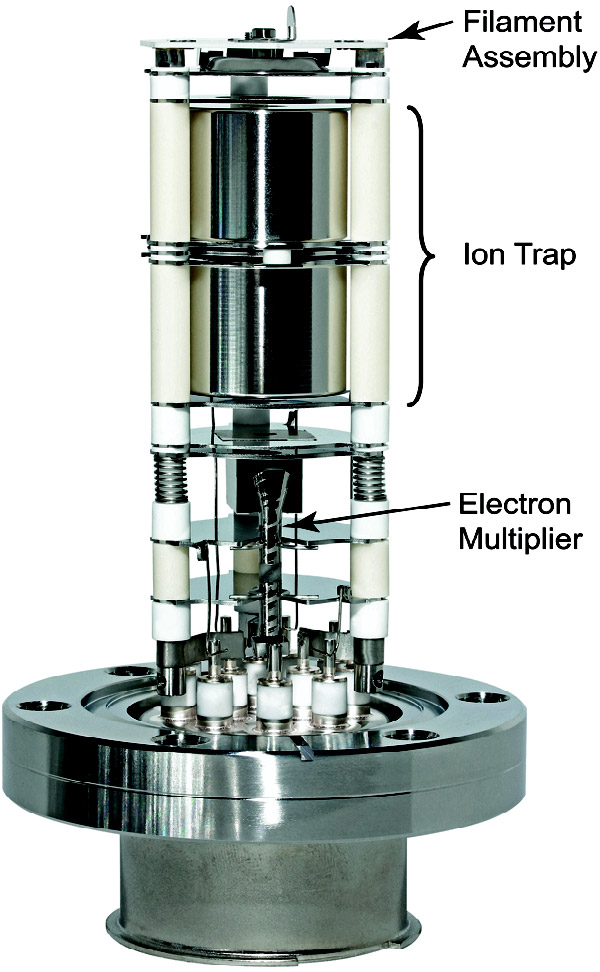

The ionizer is a filament assembly that generates ions directly inside the ion trap through electron impact ionization. An electrostatic field traps the ions, and they oscillate at their natural frequency within the ion trap. The frequency of oscillation is inversely proportional to the square root of their mass-to charge ratio – i.e. lighter ions oscillate at higher frequencies than heavier ions. The ions are ejected through an autoresonant energy pumping process using a low amplitude RF scan. An electron multiplier collects the ejected ions and produces a current proportional to the ion concentration.

Common Uses

The 835 VQM is typically used for any manufacturing or experimentation process that occurs in a vacuum (glass coating, semiconductor manufacturing, beam line gas analysis, etc.). Primary usage includes system baselining, post chamber PM verification, leak detection, contamination monitoring, process monitoring, and checking the quality of the vacuum in the system.

Setup

Field Replaceable Assemblies

The filament and electron multiplier are easily replaced by your own service technicians. Replacement kits provide everything needed –including an easy-to follow instruction guide – to assure quick, simple, and cost effective replacement, as well as maximizing system uptime.

Compact Size and Remote Mounting

The small size of the VQM gauge allows the system to be used in applications where space and weight limitations are crucial. The gauge is not mounted to the controller, thereby making the system ideal for use in harsh environments such as accelerators and beam lines where radiation is known to cause some electronics to malfunction. In addition, multiple gauges can be operated by just one VQM Controller by simply moving the interconnect cable to a different VQM gauge, thereby eliminating the requirement of multiple controllers on a process chamber or system.

UHV Compatibility

The materials, composition and construction of the 835 VQM Gauge are commensurate with standard ultra-high vacuum technology and UHV gauging including stainless steel, ceramics, and refractory materials.

High Resolution Low Mass Spectra

Unlike current quadrupole mass spectrometers, the VQM System accurately reports the spectra of low amu gases, such as helium and hydrogen, and includes hydrogen 1 in the spectra.

| Part No. | Description | Quantity In Stock |

Price EA |

Order |

|---|---|---|---|---|

| 835500U11 | MISSING PART NUMBER | CALL | ||

| 83530003M | CABLE VQM CONTROLLER-3 M 3 METER LENGTH; CONTROLLER TO MASS SPECTROMETER GUAGE | DISCONTINUED | --- | --- |

| 835400 | 835 VQM SOFTWARE SUITE | DISCONTINUED | --- | --- |

| 835100YG1D | MISSING PART NUMBER | CALL | ||

| 80120210M | MISSING PART NUMBER | CALL | ||

| 3908022YGT | TOTAL PRESSURE KIT USE WITH VQM | INACTIVE | --- | --- |

| 80230103M | VQM 3M CABLE USE WITH 835 VQM | DISCONTINUED | --- | --- |

| * Call for availability. | ||||

|

|

||||

Differential pump system for use with VQM The Differential Pump System by Granville-Phillips® extends the vacuum pressure range of the award-winning, high performance Vacuum Quality Monitor (VQM™).

Differential pump system for use with VQM The Differential Pump System by Granville-Phillips® extends the vacuum pressure range of the award-winning, high performance Vacuum Quality Monitor (VQM™).