Price: 0

Product ID : 783041

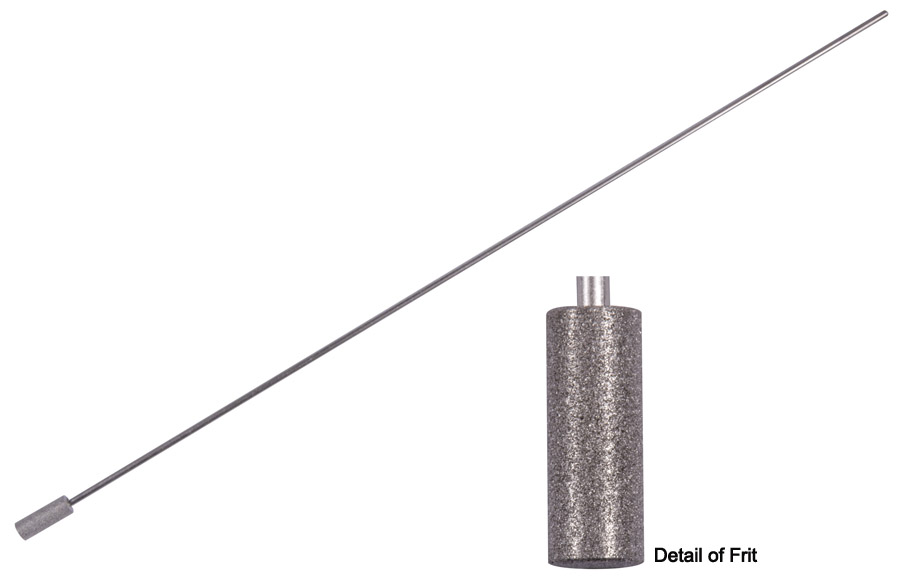

783041 Purge and Trap Stainless Steel FRIT Sparger, 16 cm long

Description

More details on associated web page:

Stainless Steel Metal Frit Spargers for the Purge & Trap System The stainless steel metal frit spargers have been designed for use with the S.I.S. purge and trap system.

Stainless Steel Metal Frit Spargers for the Purge & Trap System The stainless steel metal frit spargers have been designed for use with the S.I.S. purge and trap system.

SGE Graphitized Vespel® Ferrules

SGE Graphitized Vespel® Ferrules Vespel® ferrules contain 15% graphite and are ideal for glass and fused silica capillary columns.

Stainless Steel Metal Frit Spargers for the Purge & Trap System

Stainless Steel Metal Frit Spargers for the Purge & Trap System The stainless steel metal frit spargers have been designed for

use with the S.I.S. purge and trap system.

Purge and Trap Glass Tubes, 5 & 25 mL

Purge and Trap Glass Tubes, 5 & 25 mL All tubes are constructed from borosilicate glass with 0.5" O.D. tube ends for mating with standard 1/2" fittings.

Small Sample Spatula

Small Sample Spatula For loading small samples into Silco Coated desorption tubes

SIS Purge and Trap System

SIS Purge and Trap System The Purge and Trap System consists of two single-ball rotameters with adjustable needle valve mounted on a nylon plastic base with an 18" long mounting rod support.

Desorption Tube Fittings

Desorption Tube Fittings Fittings to connect our 1/4" O.D. GLT desorption tubes to your particular application.

Extraction Cell for Papers, Polymers & Food Containers

Extraction Cell for Papers, Polymers & Food Containers The Extraction Cell system consists of two stainless steel plates which are separated by an inter-changeable PTFE insert.

Tenax® TA Adsorbent Resin

Tenax® TA Adsorbent Resin Tenax® TA is a porous polymer resin based on 2.6-diphenylene oxide.

Short Path Thermal Desorption Tubes

Short Path Thermal Desorption Tubes After conditioning and sample loading, the ends of the tubes are fitted with stainless steel caps with seals to maintain the integrity of the medium and sample.

Aluminum Funnel for Loading Packings into Desorption Tubes

Aluminum Funnel for Loading Packings into Desorption Tubes SPTD Accessory